Proposing Surface Coating Business For Environmental Protection

Question

Task:

You are employed as an Environmental Health Officer (EHO) / Environmental Protection Officer and have received an Environmental Authority (EA) application for an ERA.

The operation of the proposed Surface Coating business will include:

- An office building which will include an office, staff lunch room, shower and toilet facilities, etc.

- a main workshop,

- a washdown bay,

- refueling facilities and

- on-site stormwater containment and treatment systems.

You are required to assess the potential environmental impacts associated with the surface coating business. Your detailed assessment will consider potential air, water and land pollutants; environmental noise, and other environmental protection / management issues. After identifying the sources of potential pollutants, their characteristics and potential impacts, you are required to identify suitable methods for managing each potential pollutant. You need to justify your decisions in the context of the principles of environmental protection and sustainable development, and relevant legislation.

You then need to develop approval conditions (conditions for an environmental authority, attach as an appendix) which would ensure government agencies would have the legal power to control all potential pollutants.

You are then required to write a report which should detail the process you undertook to identify the potential environmental impacts and appropriate management strategies, your findings in relation to the application and plans, and an explanation of the draft conditions.

Answer

Introduction

Today the rate of pollution is increasing rapidly, so it has become essential to evaluate the impact harmful effect for environmental protection which a business can provide in the atmosphere. Every business generates some pollution either in air, water, soil or noise. This report will describe a scenario for the Surface coating business establishing the business under the environmental protection act and sustainable development principles, which is necessary to evaluate while undertaking this business. For establishing the business, it needs to be taken into consideration that various areas of the business will generate pollution. Thus, the report will analyse the sources of these pollutants and the potential impact which needs to be managed effectively (Khosravi, Jha-Thakur & Fischer, 2019). In order to evaluate the potential pollution impact, it is necessary to carry out the ERA, which is an environmentally relevant activity for which environmental authority approval is required under the environmental protection act. The first section of the report will thoroughly analyse the legislative background of ERA and the type of application where the ERA will be used. Next, it will discuss the approval process of ERA in different stages. The report will further highlight the methodology and the potential pollution issues which can arise while establishing the surface coating business. All the legislative requirements associated with the identified problems have been discussed in comprehensive reports. Lastly, the information will also provide various ways to solve the issues related to the potential pollution.

Legislative background for ERAs

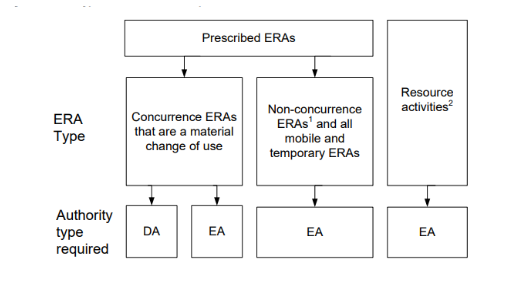

According to Anon (2021), ERAs (environmentally relevant) can be stated as agricultural activities. ERA defined under section 75 can also be noted as a resources activity defined under section 107. It is mainly the prescribed activities related to industrial and intensive animal industries, which have the potential to release emissions and impact the environment and other surrounding land uses. However, certain types of ERA fall under EA based on resource activity. For the regulatory requirement, it has been found that standard criteria have been applied for making decisions related to ERAs. Two types of ERA are DA and EA; DA is mainly used to depict the land used conditions.

On the other hand, EA is used for understanding operational needs. Though for the Surface coating business, it is not necessary to use DA EA to evaluate the potential impact from the operating conditions (Dhakal & Chevalier, 2017). Concurrence ERA is mainly the higher risk ERAs which are majorly used for material change under the planning act. Similarly, in non-concurrence, ERAs only require EA, not including the development assessment under the local planning scheme.

Though the establishment of ERA is not so easy as it requires development permission, including the application of EA under section 115 and thus has been processed under planning act 2016, resources activity mainly requires a proper resources authority for undertaking the relevant resources under legislation environmental authority act. An exercise that is generally prescribed under ERA can be said to have authorisation of EA of resources activity. On the other hand, ancillary activities, mainly listed in schedule 2, are carried out as part of resources activity.

Figure 1: Types of ERA

(Source: Anon, 2021)

Type of application of ERA

ERA application majorly follows a single application process. Still, for different types of ERA, it may address different application pathways, which mainly depends upon the authorities required. There are three different types of application like standard, site-specific and variation. For the surface coating business scenario, the site-specific application will be used as the type of ERA under environmental authority. The site-specific application will be much appropriate while defining this scenario. It includes applications that are made up of any proposed ERA that are not eligible, and thus environmental authority is specifically subject-oriented (Van Putten et al., 2018). Since the surface coating business will undertake all the operative functions, including refuelling facilities and on-site stormwater container system and treatment system. Site-specific types of ERA have undertaken the model condition, which has been developed for a particular industry. Surface coating businesses are must use a site-specific application that falls under non-concurrence ERAs. By following this type of ERA application process, it will be easier for the company to protect the environment by following all the standards and thus evaluate the potential impact it may cause.

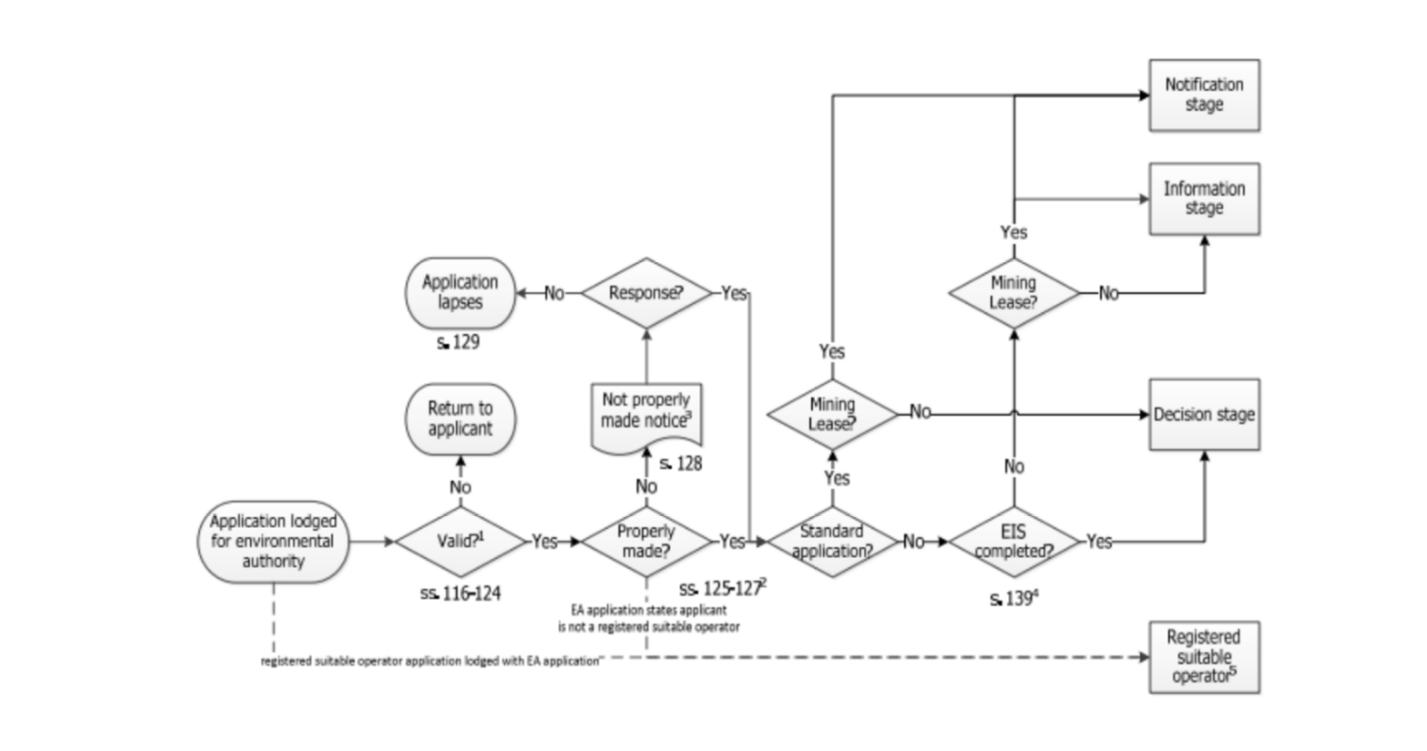

The approval process of ERA

The application of environmental authority totally depends upon the type of application of ERA. Previously it has been found that the Surface coating business has site-specific applications, so it is necessary to go through an approval process to get EA (Business Queensland, 2021). For different types of ERA, there are other ways of the approval process. A site-specific application under the prescribed ERA includes three stages: Application stage, information and decision stage.

- Application stage: The application stage is the first stage which is standard for all types of ERA. Under this stage, all the applications are checked thoroughly in order to ensure that the application has met the essential criteria under section 127. The application stage ends earlier, within ten business days after receiving the application from the client. In either case, the application stage is completed when the administering authority is satisfied with the application stage that has been compiled. If an application has not been made correctly, a notice of "not properly made application" is issued to the person who has applied for the process (Dean, Gibbons & Perkiss, 2018). Under this notice, the applicant gets 20 business days to make the required changes within the notice application. The next stage of the EA application is mainly dependent on the type of application and the kind of activity for which the approval process has been processed. The below diagram shows the operation of the application stage.

Figure 2: Approval process

(Source: Business Queensland, 2021)

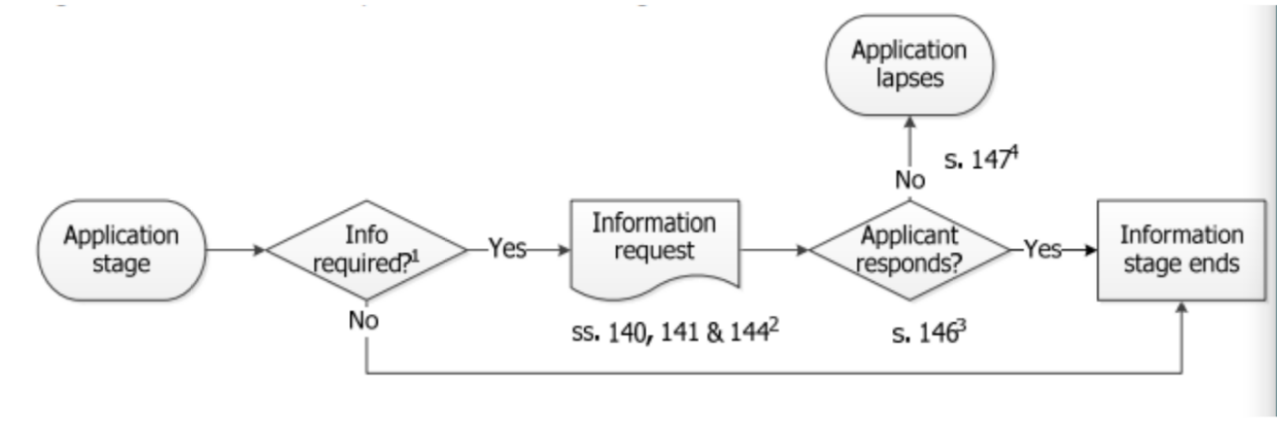

- Information stage: It is the second stage of the application process, and it can be implied to all the variations as well as site-specific environmental authority application process. At this stage, applicants' applications are thoroughly checked to see whether all the information is provided to decide the application. If all the information is correct, it further proceeds to the next stage for the site-specific application. It nearly takes 20 business days for the information request. In either case, if the information provided has some issues, then a request notice to change the data is sent to the applicant (Yao et al., 2021). Once the information request notice is issued, the applicant must respond within the provided time period. If the applicant has any issue, the applicant can request an extension of the request period. However, it will totally depend upon the administering authority whether to extend the request or not. When the administering police do not seek any response from the applicant within the denoted time, the information request notice gets lapses (Williams & Dupuy, 2017). This stage comes to an end when the information request has been issued, and the applicant responds within the stipulated time under section 146. Or else, if the information request has not been given, the authority does not need to ask for the request notice.

Figure 3: Information stage

(Source: Business Queensland, 2021)

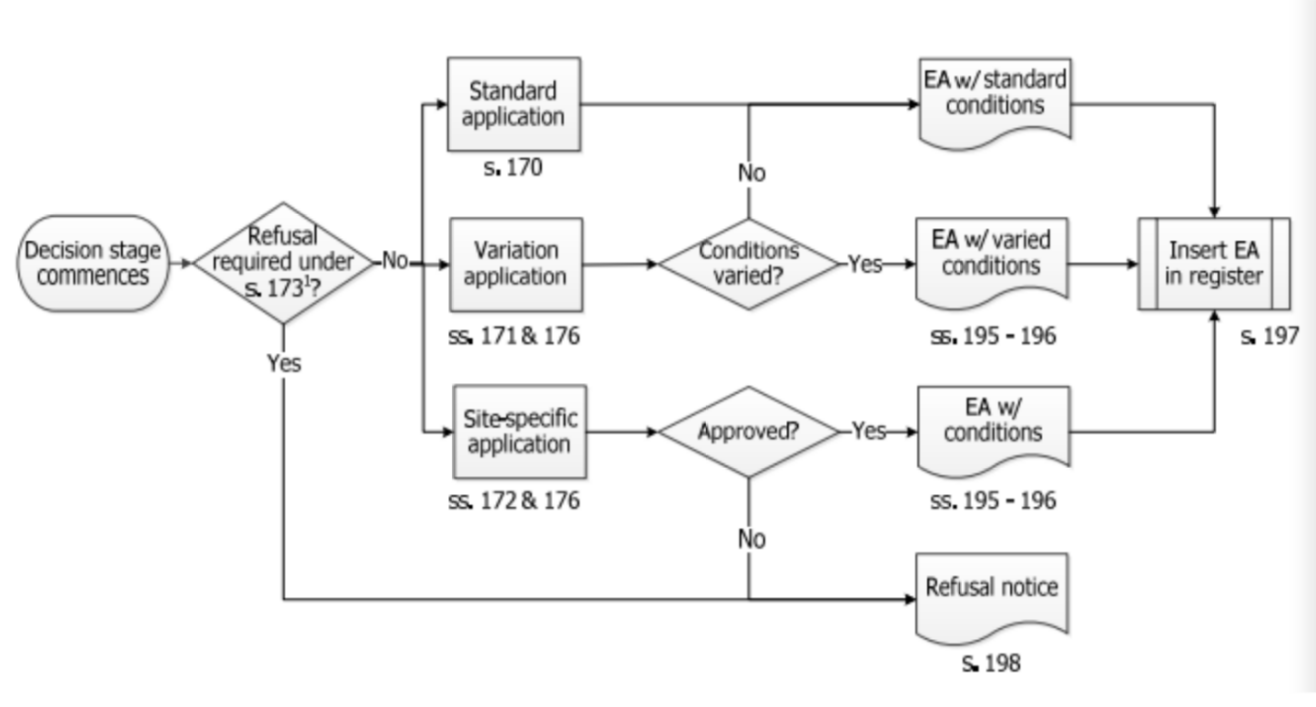

- Decision stage: It is regarded as the last stage for the approval process. The decision stage takes place once all other locations have ended. However, the decision stage is standard for all types but for site-specific. The exception is under section 167 and is majorly related to the collaborative project required under SDA. The decision stage mainly commences later, which include the day the coordinator general gives a proponent copy to the coordinator general under SDA (Durden et al., 2018). It also undertakes the days when all other stages of application have ended. The decision which has been taken about the application needs to be made within 20 days after the scene starts. If all things are approved, then the administering authority needs to issue EA to the applicant within five days.

Figure 4: Decision Stage

(Source: Business Queensland, 2021)

Identification of referral agencies

For the development of the business there has not been found any referral agencies. Being a new business, it is necessary to refer to the customer so as to gain support of the community and to increase the network. Though the whole process of identification of the referral agencies is more in providing contact information which would engage more people with the company (Kumar et al., 2019). The referral agencies can help the company in many ways by sending new clients and to provide extra information which Surface coating business needs for the perfect growth of the company. Though in this case the company has not got any referral agencies which would help the company to grow well.

Methodology

The methodology which has been chosen for the successful documentation of Environmentally relevant activity is mainly by checking the eligibility criteria and standard conditions for the surface coating business (ERA 38). Eligibility criteria basically ensures that all the constraints which are set for ensuring the environmental risk are related to the operation of ERA which are easily managed against standard conditions (Trojanowska et al., 2018). Once the eligibility criteria match with the standard conditions of the ERA then it will be easier to get a standard application form. The eligibility criteria for surface coating business has been described below:

|

Activity |

Eligibility criteria |

|

Sandblasting and powder coating |

This activity will produce coating and painting using more than 100 tonnes of materials per year, which have potential impact on the atmosphere and thus tends to pollute air. |

|

Sunshine creek |

Sunshine creek water resources is near the location which is within 100 meters which might get polluted due to the toxic materials. |

|

Surface coating plant equipment’s |

This equipment will produce the majority of the toxic materials in the air as well as noise pollution is another aspect which may pollute due to the equipment. |

|

Coating of surface |

It will include paint as well as other toxic materials like zinc, nickel and other material which are necessary for the damaged plating (Holmberg & Erdemir, 2017). Coating will include oils and dirt which may cause blaster. |

|

Deep cleaning |

Deep cleaning of metal will also produce more toxic materials as it includes rubbing of alcohol and thus with the use of cleaning baking soda and thus water will also be affected which include dusting of the lamp shades and cleaning of baseboards. |

|

Thermal spraying |

Thermal spraying improves and heated material which include various chemical means that have engaged the flammable substances which include chemical and other flammable substances that include metals, alloys and other ceramic plastic substances. |

All the activities are mainly included in the surface coating business which may pollute the environment effectively. Under this activity different pollutants are mainly included which effectively hamper the air water and noise pollution. It will potentially create a risk factor for the environment and thus may hamper the sustainability of the environment. It is necessary to make the activity based on sustainability which will ultimately not hamper the environment in future. Eligibility criteria for the business shows that each and every activity which is associated with the business is harmful which may create a negative impact on the environment (Müller et al., 2020). So, it is necessary for the business to take safety precautions while performing such activities. The business needs to take approaches which will move towards sustainability and thus will ensure that the business creates less impact on the environment.

Potential pollution issues

Surface coating business includes various environmental issues which may affect both air water and noise. Due to the release of the harmful chemical and other toxic materials it has been polluting the environment.

- Air pollution: During the spraying and sandblasting process there are a number of harmful pollutants which actually pollute the air and the other surrounding areas which create a negative impact on the environment (Ibrahim et al., 2019). The residential areas and people may get affected as the air becomes highly poisonous which ultimately affects the health of the people. Poisonous gases and other harmful materials affect the air and thus it is necessary for the business to understand the potentiality of the issue and should try to mitigate the problems. People living near the business area may have breathing and other respiratory problems. The spraying process included radioactive materials which is another harmful pollutant for the atmosphere.

- Noise pollution: It is another issue which surface coating business may provide as during deep cleaning and surface coating plant equipment which generates high noise and it ultimately affects the residential people who are living in the nearby areas (Wood et al., 2020). High frequency sounds which are released from factories ultimately affect the senior citizen and thus create a negative impact on hearing.

- Water pollution: Another potential issue which surface coating business provides to the surroundings are mainly by polluting water resources nearby. Sunshine creek has been found to be one of the nearby water resources which ultimately gets polluted due to the release of the harmful chemicals and other toxic materials (Liu et al., 2017). Sunshine creek is a local water surface which is used by the residential people for daily use and thus with the release of the toxic materials like zinc, lead and nickel during the sandblasting and other processes have affected the water seriously and thus polluted it. Especially the paints and the other coating materials which are released in the water may affect marine life effectively.

Legislative requirements

According to PowderCoatingOnline.com (2021), for establishing the surface coating business it is necessary to understand the various legislative requirements that ultimately have to meet the regulations and legislative update. Some of the regulations which surface coating business are necessary are as follows:

- VOC regulations: Volatile organic compound regulations mainly permits to operate with volatile materials. Thus, the rules basically change with the change in the location. States or places which already have high air pollution need to adopt VOC regulation for establishing the surface coating business. Since the surface coating business uses powder coating, it is mandatory to undertake VOC regulations which will provide an opportunity for the business to continue its business effectively.

- HAP regulations: Hazardous air pollutant regulations mainly track the air pollutant emission in a particular area. Surface coating businesses are mainly categorized as an area depending upon the HAP emissions. Under HAP regulation there are two important source areas which include first paint stripping and auto refinishing. It is necessary to undertake HAP regulation which will depend solely upon the area and have a major source of facilities.

Discussion

In relation to the above context it can be summed up that the surface coating business operates in various harmful pollutants and it may have a harmful impact on the environment. It is necessary to get an environmental relevance activity application which will provide permission to continue the business. Surface coating business will operate in refuelling facilities and other on-site stormwater which also include various treatment systems. In all this operation there is a high chance of releasing harmful chemicals which may affect both air, environment, noise and water (Guan, 2018). From the discussed activities it has been found that there is a high potential of releasing huge amounts of chemicals in air which may affect the health of the residential people living nearby. The legislative regulation for this surface coating business is necessary which will help the company to establish the business in a prominent basis. Undertaking these regulations will ensure that harmful chemicals are used less so as to move towards sustainability and to follow all the environmental principles effectively.

Recommendations

There are various products which require surface coating but during the establishment of the business there are many techniques which will be useful for prevention of pollution in the surface coating business.

- Maintenance of the equipment properly: Surface coating business and its equipment needs to be marinated properly and regularly. It is necessary to use properly designed equipment which will make less noise. Proper size, shape and type of coating will effectively eliminate the cross drafts and thus will help to reduce the air pressure in the atmosphere. In case of electrostatic painting it will help to turn on power and keep a clean ground which will ultimately hook up in the grounding strap. By increasing the transfer efficiency, it will effectively increase the efficiency and speed and will release less harmful pollutants.

- Reduction of thermal spray dust: It is necessary to control the spread of dust and powder which otherwise may be dreadful. It is necessary to include a proper ventilation system which will not affect the people working in the firm. There should be an entry timer which will prevent the entry of any people into the booth until the whole process is shut down. Moreover, designing an exhaust system will ensure that all the harmful gases are passed away.

- Drainage system: It is necessary to make a proper drainage system so as to pass the harmful water without realising it on nearby water areas. By maintaining a proper drainage system, it will ensure that all the water that is realised will effectively pass through drains without affecting the marine life of nearby water resources.

- Pre-Filtration modules: It is another measure which can be used prior to dry media filters which will enhance the cleaning effectively. It will capture large amounts of dust that are entertained in the airstream before it reaches the primary dust collector.

Conclusion

To sum up, from the above report, it can be stated that for establishing a Surface coating business, it is necessary to gain the application of EA. As an environmental officer, it is essential to gain the approval of the ecological relevance authority. It can be evaluated from the above process that the surface coating business mainly includes the refuelling facilities and on-site stormwater treatment systems. So, it falls under the site-specific type of application for which different approval stages have been described. Additionally, the methodology has been undertaken to ensure the potential impact of the pollution which the business may cause. It shows that after establishing the surface coating business, it is affecting the air, noise, and soil tremendously, for which the company needs to take practical steps. These potential pollution issues have been evaluated from the methodology section, which depicts that with the proper establishment of the legislative requirements and thus have proposed various recommendations during the approval process. The coating materials discussed in the above report also state that there is a high potentiality in the environment.

References

Anon (2021). Retrieved 12 October 2021, from https://environment.des.qld.gov.au/__data/assets/pdf_file/0021/90129/era-gl-environmental-authority-approval-process.pdf

Dean, B. A., Gibbons, B., & Perkiss, S. (2018). An experiential learning activity for integrating the United Nations Sustainable Development Goals into business education. Social Business, 8(4), 387-409. https://www.ingentaconnect.com/content/westburn/sb/2018/00000008/00000004/art00004

Dhakal, K. P., & Chevalier, L. R. (2017). Managing urban stormwater for urban sustainability: Barriers and policy solutions for green infrastructure application. Journal of environmental management, 203, 171-181. https://www.sciencedirect.com/science/article/pii/S0301479717307478

Durden, J. M., Lallier, L. E., Murphy, K., Jaeckel, A., Gjerde, K., & Jones, D. O. (2018). The Environmental Impact Assessment process for deep-sea mining in 'the Area'. Marine Policy, 87, 194-202. https://www.sciencedirect.com/science/article/pii/S0308597X17305316

Guan, S. W. (2018, April). Abrasive Blasting Surface Preparation–Does the Pipeline Coating Industry Really Understand It?. In CORROSION 2018. OnePetro. https://onepetro.org/NACECORR/proceedings-abstract/CORR18/All-CORR18/NACE-2018-11245/126124

Holmberg, K., & Erdemir, A. (2017). Influence of tribology on global energy consumption, costs and emissions. Friction, 5(3), 263-284. https://link.springer.com/article/10.1007/s40544-017-0183-5

Ibrahim, K. A., Naz, M. Y., Shukrullah, S., Sulaiman, S. A., Ghaffar, A., & AbdEl-Salam, N. (2019). Controlling nitrogen pollution via encapsulation of urea fertilizer in cross-linked corn starch. BioResources, 14(4), 7775-7789. https://ojs.cnr.ncsu.edu/index.php/BioRes/article/download/BioRes_14_4_7775_Nitrogen_Pollution_Encapsulation

_Urea/7077

Khosravi, F., Jha-Thakur, U., & Fischer, T. B. (2019). Evaluation of the environmental impact assessment system in Iran. Environmental Impact Assessment Review, 74, 63-72. https://www.sciencedirect.com/science/article/pii/S0195925518302038

Kumar, P., Chauhan, S. R., Pruncu, C. I., Gupta, M. K., Pimenov, D. Y., Mia, M., & Gill, H. S. (2019). Influence of different grades of CBN inserts on cutting force and surface roughness of AISI H13 die tool steel during hard turning operation. Materials, 12(1), 177. https://www.mdpi.com/1996-1944/12/1/177/pdf

Liu, S., Hu, Q., Qiu, J., Wang, F., Lin, W., Zhu, F., ... & Ouyang, G. (2017). Enhanced photocatalytic degradation of environmental pollutants under visible irradiation by a composite coating. Environmental science & technology, 51(9), 5137-5145. https://pubs.acs.org/doi/abs/10.1021/acs.est.7b00350

Müller, A., Österlund, H., Marsalek, J., & Viklander, M. (2020). The pollution conveyed by urban runoff: a review of sources. Science of the Total Environment, 709, 136125. https://www.sciencedirect.com/science/article/pii/S0300944018307847

-PowderCoatingOnline.com, P. (2021) Powder Coating Regulations - American Coatings Association -, PowderCoatingOnline.com. Available at: https://www.powdercoatingonline.com/american-coatings-association-legislative-regulatory-policy-update/ (Accessed: 19 October 2021).

The assessment process for environmental authority applications | Business Queensland. (2021). Retrieved 13 October 2021, from https://www.business.qld.gov.au/running-business/environment/licences-permits/applying/assessment

Trojanowska, J., Kolinski, A., Galusik, D., Varela, M. L., & Machado, J. (2018). A methodology of improvement of manufacturing productivity through increasing operational efficiency of the production process. In Advances in Manufacturing (pp. 23-32). Springer, Cham. http://repositorium.uminho.pt/bitstream/1822/50892/1/139-144_IMPROVING%20PRODUCTIVITY%20AND%20%20STANDARD%20TIME%20UPDATING%20IN%20AN

%20INDUSTR....pdf

Van Putten, I. E., Cvitanovic, C., Fulton, E., Lacey, J., & Kelly, R. (2018). The emergence of social licence necessitates reforms in environmental regulation. Ecology and Society, 23(3). https://www.jstor.org/stable/pdf/26799167.pdf

Williams, A., & Dupuy, K. (2017). Deciding over nature: Corruption and environmental impact assessments. Environmental Impact Assessment Review, 65, 118-124. https://open.cmi.no/cmi-xmlui/bitstream/handle/11250/2475178/Deciding%20over%20nature:%20Corruption%20and%20environmental

%20impact%20assessments?sequence=1

Wood, D., Shaw, S., Cawte, T., Shanen, E., & Van Heyst, B. (2020). An overview of photocatalyst immobilization methods for air pollution remediation. Chemical Engineering Journal, 391, 123490. https://www.sciencedirect.com/science/article/pii/S1385894719329031

Yao, H., Yao, B., Wu, S., & Han, J. (2021). Responses and Thoughts of Transportation Construction Projects in the Reform of Environmental Review and Approval System in the New Situation. In E3S Web of Conferences (Vol. 233). EDP Sciences. https://search.proquest.com/openview/a2b2b4d7764f5ceb2b27519990568989/1?pq-origsite=gscholar&cbl=2040555