Lean Six Sigma Management on Specific Sectors

Question

Task:

Discuss the management of Lean Six Sigma with environmental oriented focus on specific sectors (e.g. manufacturing, construction, healthcare, etc.)

Lean Six Sigma Approach used in Industry (~3000 words)

Lean intends to minimise waste, increases speed, maximise value; Six Sigma helps the organisation to measure, analyse, reduce and control defects. An integrated approach can help the firm to reap the benefits of process excellence faster. The present body of knowledge reports both success and failures of such integrated philosophy. The success primarily on the macro-environment (including social, political and environmental dimensions) and micro-environment (including leadership, skill, culture) of the firm. This task will develop your skills and the application of Lean and/or Six Sigma approaches and theories in a real world context or firm (manufacturing or service industries) in which you are regularly involved. Specifically, you are expected to select and answer one of the following topics of interest (choose one):-

Q1: How can firms align, adapt and deploy Lean/Six Sigma Strategies to effectively response and support the current environmental challenges without jeopardising their business success?

Q2: Discuss the challenges of Lean Six Sigma application to support the shift towards greener operations and supply chains.

Q3: Discuss the management of Lean Six Sigma with environmental oriented focus on specific sectors (e.g. manufacturing, construction, healthcare, etc.

Answer

Introduction

Concept of Lean Management:

The concept of Lean management discussed in this study of Lean Six Sigma Management is considered as an approach for organization management, which revolves around the concept of continual improvement. It is generally considered as a long-term approach which systematically tends to achieve even minutely increased changes in the business processes for improving the concerned efficacy and quality. The primary focus of the concept of lean management is to maximize the value of outcomes in accordance with the immediate potential of the entity concerned (Rotter et al., 2019).

Lean Management

(Source: Martínez-Jurado, P, & Moyano-Fuentes, 2018)

Concept of Six Sigma Strategy

Six Sigma is considered as the quality management set of tools and techniques, which aids several businesses to improve their immediate processes, services or products, by the identification, evaluation and elimination of the defects. The main purpose of the Six Sigma Management Strategy is to manage and control the quality services bestowed in the management and associated business processes for eliminating the uncertainties emerging throughout the procedure (Yadav & Desai, 2016). It is basically a data-driven approach for obtaining continual improvement through eliminating the defects. It is a measure for assessing the performance of the processes.

Figure 2: Six Sigma Strategy

(Source: Lande et al., 2016)

Concept of Lean Six Sigma

Lean Six Sigma Management has been considered as a method of compliance relying on the cumulative team effort for improving the performance through systematic removal of waste and reduction of variance (Laureani & Antony, 2017). The main focus of the concept is to alleviate the power of Lean and Six Sigma, for improving the productivity in lieu of the improvements in quality and associated elimination of variance. The process of redesigning also aids in the reduction of lead time, waste elimination and reframing the inventory levels.

Figure 3: Lean Six Sigma

(Source: Albliwi et al., 2015)

Discussion

Environment-oriented focus of manufacturing industries, its necessity and importance:

Development in the world has been considered as the rapidity of the advancements in the process of industrialization. The government possesses a vision of increasing the contribution of the manufacturing sector in the GDP of the country. It brought about a drastic change in accordance with the concept of employment. As for instance, there is the persistence of several industrial and manufacturing zones, which are of enormous size. The associated risks with the concept of industrial and manufacturing development includes the enhanced levels of pollution as well as the overutilization of natural resources and the increment of wastes and waste water thereby exposing the endangered ecosystems. Pollution which proximate due to the hazardous substances emitted from the industry and the overused natural resources, exposes the sustainability of development at potential risks. Several projects have to be laid down by various companies for showcasing their ambit of the technical solutions which can be incorporated for upscaling and replicating the adequate business management models required for attaining sustainability in the process of manufacturing. The primary objective of the concept is to enable the actors of the private and public sector for the joint implementation of the strategies for achieving efficacy, climate-friendly development of industry collaterally aligned with the concept of environment-orientation.

For the accomplishment of the motive of incorporating the sustainable trends in accordance with the environment-oriented concerns, the projects should run at national levels and other associated project site levels. This aids in the proper addressal of the conveyance of wastewater, its associated treatments, the process of recycling and the associated requisite process of modification in various individual industries. These are achieved through a scheme of skill development, training, construction of the requisite technology platform for assessing the purpose of transfer and other associated technology of partnerships. The introduction and development of policies for enabling the framework and various support programmes, prevents and reduces the level of pollution. It also improves the resource efficiency in the concerned industrial zones in accordance with the support received at national level and state level. The focus on environment, as depicted by the manufacturing industries in modern-day market scenario, is important owing to the fact that it acts as a significant way of gaining a competitive edge in the market, while gaining sufficient customer satisfaction and establishing a strong brand image within the market. The ‘green’ manufacturing initiatives by the companies also allows them to achieve higher productivity and profitability within the market segment.

Outline of the Lean Six Sigma principles and their importance

The principles of Lean Six Sigma Management and its importance are:

1) The focus should be bestowed concisely on the customers:

It is one of the prime motives of the Lean Six Sigma principles. It has been one of the most prudent essentials for a manufacturing company till date. However, irrespective of the type of business pursued, the primary preference should always be given to the customers. Thus, the drastic changes, which have been apprehended to be incorporated in the management procedure of a manufacturing company, it should be in accordance with the desirability of the consumers or customers concerned. Attraction of new customers will be conducted in the course of time, thereby collaterally increasing the sales through the incorporation of new changes in the manufacturing standards of a company.

2) Assessing the value imposed by the stream of the concerned company:

This has been the quintessential determinant for assessing the efficacy of the principles. It is for evaluating the steps within a mentioned ambit of processes and for identifying the areas of waste. A value stream map encompasses and enumerates every single step, inclusive of purchasing the parts, assemblance of the parts and the distribution of the finished products, which is followed by the organizational leaders within departments (Welch, Rimes, & Bozeman, 2015).

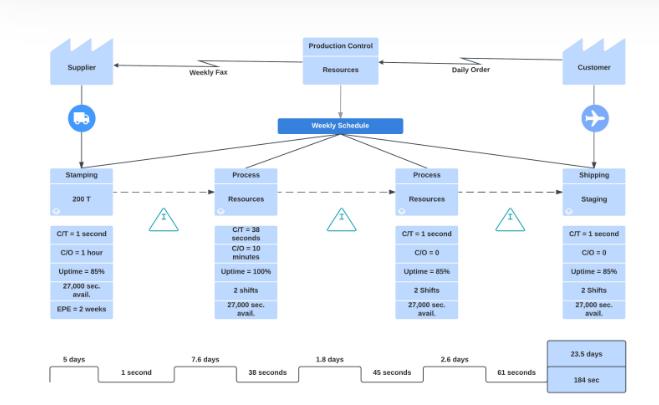

Figure 4: Value Mapping

(Source: Bocken et al., 2015)

3) Extracting the trash: Once the value stream has been incorporated, the identification of the problem can be done effectively in accordance with maintaining the workflow and thereby solving them effectively. The value stream map primarily emphasizes the ‘cause and effect’ of the arising anomalies (Hossen et al., 2017). The value stream map should be basically for highlighting the problems that arises, thereby identifying the root cause of the issue. The company value map can also be used for highlighting the areas of smooth working which in turn enhances the morale and composure of the concerned workforce of the manufacturing company, while enhancing the skills of the employees and the interim organizational positively.

Figure 5: Cause and Effect Diagram

(Source: Harrington, 2016)

4) Continual evaluation of performances:

The applicability of continuous evaluation and monitoring processes on the manufacturing companies can be easily estimated from the fact that owing to the fast-changing business environment, the organizations unable to maintain the pace loses out to their significant competitors. The change cannot be brought into the organization unless incorporated tactfully. For instance, the workforce tends to act the similar way, unless they are enlightened with the standardized form of practices for invoking sustainability in accordance with the environment-oriented concern. A work-process map can be incorporated by several companies for mentioning the changes brought about in the workflow of the company, so as to enlighten the workers in accordance with the proposed changes (Sunder, 2016).

Figure 6: Lean Six Sigma Process Map

(Source: Antony et al., 2017)

5) Incorporating a changed culture and flexibility

This process helps in the achievement of appropriate implementation of the required changes in the manufacturing company in accordance with the environment-oriented concerns. Several changes are to be incorporated for the implementation of Lean Six Sigma, for which the departmental leaders are primarily responsible. The most important aspect of it is the encouragement of employees for accepting and understanding the motive of the change, which is explained by the leaders. It is to be also understood that the appropriateness of the explanation provided to the employees, in accordance with the incorporated changes, determines the impact it creates on the employees.

The cultural shift is determined by the innovative way of carrying out the work and removing the wastes effectively, while keeping in mind the organizational culture and the skills of the employees. The concept of waste removal and recycling of recyclable wastes, encourages the employees and the associated managerials to cater to the matter and thereby effectively using it for the greater good of the company. Therefore, it is to be understood that, the methodology of Lean Six Sigma encompasses the best of Six Sigma and Lean Methods of the project management. Thus, optimization of the process of improvement can be duly achieved through following the principles of Lean Six Sigma Management.

Implementation of Lean Six Sigma in Operations Management

Operations Management encompasses the implementation of such business practices, which helps in bringing about maximum efficiency within organizations, while enhancing the productivity and profitability of the businesses positively. Within manufacturing firms belonging to the automobile or similar other sectors, there are basically eight different kinds of lean wastes which needs to be managed efficiently, for bringing about maximum efficiency, which can be summarized as DOWNTIME (Whitaker et al., 2018). The management of the DOWNTIME wastes discussed in this study of Lean Six Sigma Management is also essential for the organizations who are working towards the establishment of a ‘green’ environment. The designing, operations and maintenance of the systems responsible for the manufacturing of the products within organizations like Toyota and others specifically complies with the regulation of generation of DOWNTIME wastes, especially overproduction and extra-processing.

Figure 7: DOWNTIME wastes

(Source: Phillips et al., 2018)

Defects within the manufacturing systems are mainly described as those aspects within the products or services manufactured and marketed by the companies which remain unsuccessful in meeting the demands of the customers within the imminent market, thus leading to customer dissatisfaction. Consciousness about the environment has been increasing at an infectious rate among customers, mainly within the automobile and FMCG (Fast Moving Consumer Goods) industry sector, which mandates companies to manufacture vehicles with low impact on the environment and ‘cruelty-free’ products respectively, failing which the demands of the customers are not appropriately satisfied. Owing to tough competition, the sectors and all companies are striving to reduce their respective ‘carbon footprints’, non-compliance with the stated demand of the customers might lead to loss of customers, which would be a dear price for the companies. Under some circumstances, application of the DMAIC model of the Lean Six Sigma Management is the best-suited option (Powell et al., 2017). A specific Quality management team is set up usually, within the organizations, who are responsible for two phases of activities, the first encompassing defining the imminent problem, measuring the extent of impact that the problem exerts on the productivity and profitability of businesses and analyzing the root cause of the issue. On the other hand, the second phase encompasses, in addition to implementation of the solution, verifying its applicability and maintaining the process in which the solution is being implemented, for the longest possible time, within the organization.

Extra-processing is another process which leads to generation of significant waste within manufacturing companies like Unilever and Toyota, which, when striving to provide the best return-on-investment for customers, often goes overboard and develops products. This often leads to generation of unnecessary waste, which needs to be minimized through the implementation of Lean Six Sigma principles. Utilizing value stream maps and continual performance evaluation of the units, while matching the same with the needs prediction of the customers, received from market research, serves as an effective way of curbing extra processing, while ensuring that ‘green’ methods are resorted to, in every step, to minimise the impact on the environment.

Figure 8: DMAIC of Lean Six Sigma

(Source: Thomas et al., 2016)

Implementation of Lean Six Sigma in Supply-Chain Management

Supply-chain management encompasses the categorical flow of goods and associated services inclusive of all processes which tend to transform the raw materials into the final products. It categorically enumerates the activities of the supply-side of a business activity for maximizing the value of the customers thereby gaining a competitive advantage in the concerned market. It can duly be achieved through the process of 5S of the Lean Six Sigma management.

The utilization of the 5S of the Lean Six Sigma will enhance the viability of the supply chain management thereby enhancing the behavior of reducing waste and optimization of productivity (Albliwi et al., 2015). The principle will aid in reducing the errors while eliminating the wastes and causation of the same.

Sort: It is the procedure of sorting and arranging the agile responsiveness of the suppliers of a manufacturing company in accordance with the desirability of the customers. It is considered as the first vital step of creating an effective supply chain, which categorically fulfills the demands and needs of the customers. It essentially evaluates the progress of an organization whilst determining the quality and effectiveness of the delivery. The channelization of restricting the emerging jeopardy, provides the concerned company with a ground of excellence and progression, in accordance with fulfilling the needs and demands of the customers.

Set in order: For proper implementation of the Lean Six Sigma in the supply chain management of the manufacturing company, the managers have to realize that the decrement of the order fulfillment time is the major concern, while considering the skills of the employees and taking care not to hamper the organizational culture in any significant way. It helps in reviewing the system of fulfilling order thereby effectively spotting the areas in accordance with the high degree of wastes and related variance. The identified inefficiencies will thus be removed with precision and appropriateness collaterally aligned with the maintenance of quality.

Shine: Implementation of the Lean Six Sigma in the supply chain management will enhance the optimization of the fulfilled order. It helps in the evaluation of efficiently reducing and eliminating the wastes aligned in the procedure of manufacturing a concerned product. Most of the benefits in lieu of the supply chain will be effectively removed from the procedure of mistake-proofing, which further prevents the emerging human errors.

Standardize: The standardization of the fulfillment of order will grant the company a competitive advantage over the existing competitors in the market. It becomes standardized when a manufacturing company delivers the concerned product or services with accurate documentation and without any damage in the time of delivery. The process of Six Sigma plays its role in optimizing the fulfillment of order through spotting problems within the system as well as identifying the outdated process of planning collaterally aligned with ineffective execution and the respective departmental leaders ensure the maintenance of the same, in order to help the organization survive in the external market conditions.

Sustain: The sustainability of Lean Six Sigma management processes does not add value to the customers. It directly influences their betterment, through analysing the persisting discrepancies which might hinder the progress and sustainability of the manufacturing company. The process of lean targets the major sources of waste. It helps the company to attain sustenance through the adequate depiction of environment-oriented concerns for a concerned company.

Thus, it can be duly understood that consciousness in accordance with the environment has been increasing at an alarming rate among customers, mainly within the automobile and FMCG sector of the industry, which mandates companies to manufacture vehicles with low impact on the environment and ‘cruelty-free’ products respectively, failing which the demands of the customers are not appropriately satisfied. Thus, the complete cycle of the implementation of 5S in the Supply Chain management is connected successfully and with removing the prevailing jeopardy.

Figure 9: 5S of Lean Six Sigma

(Source: Chugani et al., 2017)

Success and failures of the implementation of Lean Six Sigma Management processes

The success stories for the implementation of Lean Six Sigma Processes in the manufacturing industries or companies are:

- a) The reduction of energy-related costs, which primarily focuses on the reduction of expenses in lieu of reducing the wastage of resources at the time of manufacture Incorporating energy-efficient changes through the incorporation of Lean Six Sigma, yields in the enhancement and alleviation of the schedule of production.

- b) The reduction of tax incentives in lieu of the sustainable approach embedded through the Lean Six Sigma Processes, encourages the concerned manufacturing company to implement several sustainable trends in the company.

- c) Attracting new customers thereby collaterally increasing the sales is the main motive for implementing new changes in the manufacturing standards of a company. This has been the main concern and advantage for the implementation of Lean Six Sigma Management Processes.

- d) The environment-oriented concerns has led to the increase of societal impacts which directly affects the profitability of the company. The reduction waste duly performed by the application of Lean Six Sigma Processes enhances the image of the company. It has been duly observed that the implementation of the changes will imbed lesser amount of carbon footprints in the environment thereby reducing the number of toxins emitted in the atmosphere, which would thus, benefit the nation and the world itself, with improved quality of air and greater non-renewable energy resources.

- e) The concept of boosting the morale of the workforce and the aligned innovations through , has been the main motivation for the incorporation of environment-oriented concerns in the manufacturing company.

- f) The enhanced role-play of the supply chain management in dealing with the inefficiencies and associated removal of wastes through the introduction of green vehicles and other possible measures, gives the concerned company a potential competitive advantage.

The failures in the implementation of the Lean Six Sigma Processes are:

The Lean Six Sigma categorically minutely inspects the processes of business, thereby generating massive amount of categorical data, thereby leading to the consumption of time and complication of procedures (Morais et al., 2015). In lieu of the process being for the improvement of quality, the processed roots and the adoption of protocols, generally lead to the increment of the overall costs.

The implementation Six Sigma gives rise to a problem, as the company focuses on the principle oriented policies and thereby ignores the specific mission or policy of the company, in accordance with its mission and vision of the company. Concerning the small-scale businesses, the constrainment lies on the innovative ideas; this favors creativity, and categorical innovation, this minutely requires the implementation of risk assessment. Lean Six Sigma management incorporates the training of the employees without any formal notice or other feasibility, in accordance with the cost of implementing Lean Six Sigma. Lastly, even a rigorous training is needed for grasping the system of enlightening the concerned employees.

Conclusion

It can be very well observed that, the concept of Lean Six Sigma Management enhances the production processes of a company, through the process of waste elimination and effective reduction of variance. The concept of Lean eradicates all possible types of waste, whereas, the concept of Six Sigma is bestowed with the burden of reducing the process of variance. However, it is also to be understood that the major cost and other underlying posed disadvantages hinder its implementation in several small-scale businesses. Thus, it can be stated that the implementation of Lean Six Sigma process possess both pros and cons for the concerned company.

Reference List

Albliwi, S. A., Antony, J., & Lim, S. A. H. (2015). A systematic review of Lean Six Sigma for the manufacturing industry. Business Process Management Journal, 21(3), 665-691.

Albliwi, S. A., Antony, J., & Lim, S. A. H. (2015). A systematic review of Lean Six Sigma for the manufacturing industry. Business Process Management Journal, 21(3), 665-691.

Antony, J., Rodgers, B., & Cudney, E. A. (2017). Lean Six Sigma for public sector organizations: is it a myth or reality?. International Journal of Quality & Reliability Management, 34(9), 1402-1411.

Bocken, N. M. P., Rana, P., & Short, S. W. (2015). Value mapping for sustainable business thinking. Journal of Industrial and Production Engineering, 32(1), 67-81.

Chugani, N., Kumar, V., Garza-Reyes, J. A., Rocha-Lona, L., & Upadhyay, A. (2017). Investigating the green impact of Lean, Six Sigma and Lean Six Sigma: A systematic literature review. International Journal of Lean Six Sigma, 8(1), 7-32.

Harrington, H. J. (2016). Cause-and-Effect Diagram. In The Innovation Tools Handbook, Volume 2 (pp. 73-82). Productivity Press.

Hossen, J., Ahmad, N., & Ali, S. M. (2017). Lean Six Sigma Management An application of Pareto analysis and cause-and-effect diagram (CED) to examine stoppage losses: a textile case from Bangladesh. The journal of the textile institute, 108(11), 2013-2020.

Lande, M., Shrivastava, R. L., & Seth, D. (2016). Critical success factors for Lean Six Sigma in SMEs (small and medium enterprises). The TQM Journal, 28(4), 613-635.

Laureani, A., & Antony, J. (2017). Leadership characteristics for lean six sigma. Total Quality Management & Business Excellence, 28(3-4), 405-426.

Martínez-Jurado, P. J., & Moyano-Fuentes, J. (2018). Lean Management and Supply Chain Management: Interrelationships in the Aerospace Sector. In Operations and Service Management: Concepts, Methodologies, Tools, and Applications (pp. 1208-1242). IGI Global.

Morais, V. R., Sousa, S., & Lopes, I. D. S. (2015). Implementation of a lean six sigma project in a production line. Lecture Notes in Engineering and Computer Science, 2, 847-852.

Phillips, L., Morris, A., Innes, G., Clark, A., & Hinden, P. M. (2018, November). Drilling Waste Management–Solutions that Optimise Drilling, Reduce Well Cost and Improve Environmental Performance. In Abu Dhabi International Petroleum Exhibition & Conference. Society of Petroleum Engineers.

Powell, D., Lundeby, S., Chabada, L., & Dreyer, H. (2017). Lean Six Sigma and environmental sustainability: the case of a Norwegian dairy producer. International Journal of Lean Six Sigma, 8(1), 53-64.

Rotter, T., Plishka, C., Lawal, A., Harrison, L., Sari, N., Goodridge, D., ... & Willoughby, K. (2019). What is lean Management in Health Care? Development of an operational definition for a Cochrane systematic review. Evaluation & the health professions, 42(3), 366-390.

Sunder M, V. (2016). Lean Six Sigma project management–a stakeholder management perspective. The TQM Journal, 28(1), 132-150.

Thomas, A. J., Francis, M., Fisher, R., & Byard, P. (2016). Implementing Lean Six Sigma to overcome the production challenges in an aerospace company. Lean Six Sigma Management Production Planning & Control, 27(7-8), 591-603.

Welch, J., Rimes, H., & Bozeman, B. (2015). Public value mapping. Public Value and Public Administration, 131-146.

Whitaker, D. A., Egan, D., OBrien, E., & Kinnear, D. (2018). Application of Multivariate Data Analysis to machine power measurements as a means of tool life Predictive Maintenance for reducing product waste. arXiv preprint arXiv:1802.08338.

Yadav, G., & Desai, T. N. (2016). Lean Six Sigma: a categorized review of the literature. International Journal of Lean Six Sigma, 7(1), 2-24.