Project Management Assignment: Construction Of M6 Motorway Project

Question

Task:

Brief

Balfour Beatty have successfully won the tender to construct the widening of the M6 motorway, Stafford. This includes the construction of a gabion retaining wall next to a field. Details of the proposed gabion retaining wall are given at the end of this project brief in the Appendix. This includes a cross section and construction details. These details are also given on Moodle.

As a new project manager with Balfour Beatty, your senior manager has asked you to produce a detailed programme for the construction of a retaining wall between chainage 210 m and chainage 310 m. The wall is longer than this but you are only required to programme 100 metres.

Contract Arrangements

Due to accessibility problems, it will not be possible to enter into a contract with the client until 5th October 2020 (the NEC3 contract date). The site will only become available to actually start work on 19th October 2020 (the NEC3 access date). As this is an important part of the construction of the project, the retaining wall needs to be completed by 12th February 2021. This completion date is a very important date in the contract but the client can be persuaded to be flexible on it. The construction of the carriageway and footway are not included in this phase of the project.

Please note the following

The first operation is to set up the site compound which will house site offices, utilities, storage and welfare facilities in compliance with CDM regulations and then the site boundary fencing around the area of the proposed works. Your organisation has agreed with a local farmer that a nearby field with access from the B123 road may be used to set up the site compound. The field is adjacent to the site of the proposed gabion retaining wall.

The following should be taken into consideration for programming

Time constraints:

i. Assume a 5 day working week.

ii. Work must begin on a Monday

iii. The site boundary fencing around the area of the proposed works takes not less than one week.

iv. The entire site compound set up takes not less than two weeks.

v. Assume it takes a minimum of twenty days to excavate and another twenty days to backfill.

vi. Removal of the site boundary fencing and site compound takes 1 week.

Construction constraints:

i. The construction processes allow the footing to be constructed in only 5-metre-long bays with each bay taking not less than a day.

ii. Installation of the entire gabion retaining wall takes a minimum of thirty days.

iii. Placement of gabions on concrete footing may commence only after a minimum of 7 days, when the footing has obtained sufficient strength.

iv. It will be necessary to include engineered fill (e.g.6F2) for approximately 50 metres behind the gabion wall.

Use the video below as a guide on gabion basket installation:

https://www.youtube.com/watchv=pk6Y9syn0NU

Part 1

Based upon your knowledge of the Project Management and time management processes, perform the following tasks:

a) In no more than 300 words explain the following Project Management techniques;

• Work Breakdown Structure (WBS)

• Precedence Diagram Method

• Critical Path

• Fast tracking

• Crashing

• Float/slack

b) Draw a Work Breakdown Schedule (WBS) for the construction element of the project including setting up and clearance of site. The WBS must clearly show phases, deliverables, work packages and activities. The WBS should contain a sufficient number of activities to show the client that you understand the construction process and to aid in later programme control. You should include task IDs in the WBS.

c) Using the WBS, produced in ‘b’ above, produce a project schedule (manual Gantt chart (project programme) using MS Excel as taught in tutorials) and allocate reasonable estimates for durations and labour resources for the identified activities. Show days in day numbers and not dates.

d) Manually produce a precedence diagram for the construction phase of the project based upon your WBS and project schedule from tasks b) and c) above. Your diagram must be in standard notation and show your proposed critical path.

Answer

Part 1

Descriptions and definition of terms

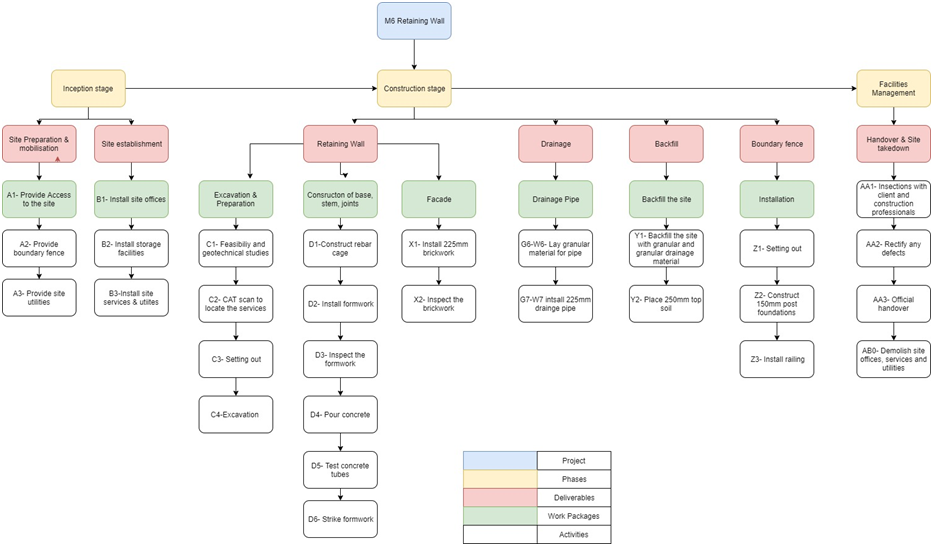

1. Work Breakdown Structure (WBS)

This refers to a visual representation of the deliverables of the construction project. A work breakdown structure is an outcome oriented rankedclassification of work to be carried out by the project team, in reference to Project Management Body of Knowledge (PMBOK)(Siami-Irdemoosa, et al., 2010). The work breakdown structure illustrates the map of the project; showing the major steps and the sub steps to be followed up to the completion of the construction process.

2. Precedence Diagram Method

A precedence diagram method (PDM) is defined by the Code of Estimating Practice as a method of creating a reasonable network using nodes as a reference of the project activities by connecting them via lines that illustrate dependencies (The Chartered Institute of Building, 2009). The PDM is a technique that visually depicts the construction tasks and their scheduled program. The PDM is used to establish the critical path of construction

3. Critical Path

Critical path refers to the longest path, with the longest duration, in which an order of interdependent tasks must be undertaken before the project is declare complete. The critical path also illustrates the minimum period required for the project to be completed(R. & Norman, 2009).

4. Fast tracking

Fast tracking comprisesof overlapping tasks that were originally scheduled consecutively or optimizing the schedule in other areas. This may involve various solutions such as splitting longer tasks to smaller portions to compress more work into a shorter amount of time, minimizingdelays between tasks, diminishing the scope to eradicate less significant tasks or a blend of resource additions and planned activity variations(Bathhurst & Butler, 2010).

5. Crashing

Crashing refers to a program compression technique by incurring a higher cost for a minimised period of construction.

6. Float/slack

Float refers to the period of time that an activity may be delayed with no effects on the timely delivery of subsequent tasks and overall project completion date(M., 2002).

Work Breakdown Structure (WBS)

The figure below shows the work breakdown structure (WBS) for the M6 motorway project(See attached pdf file):

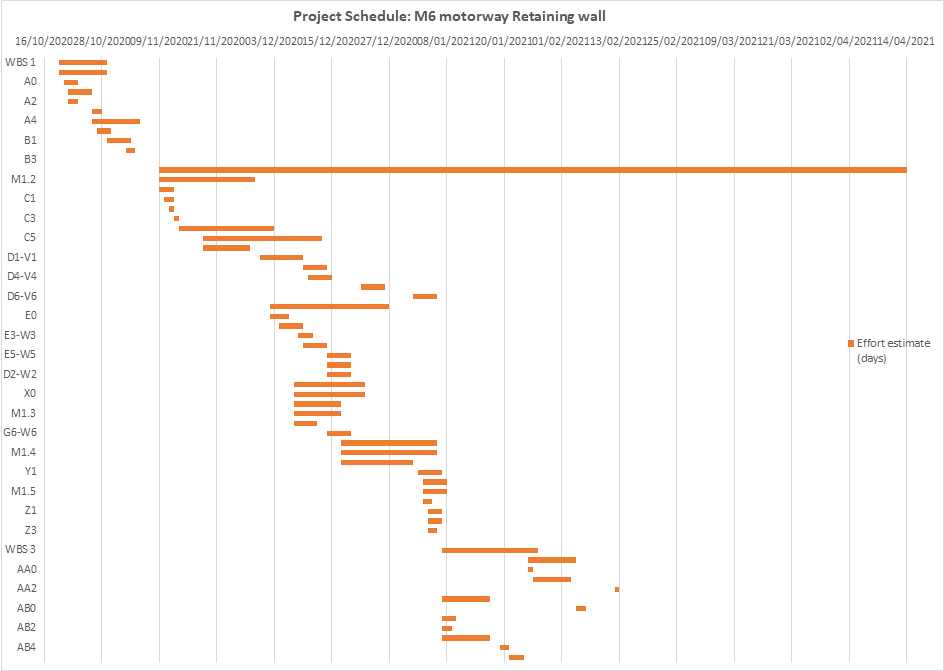

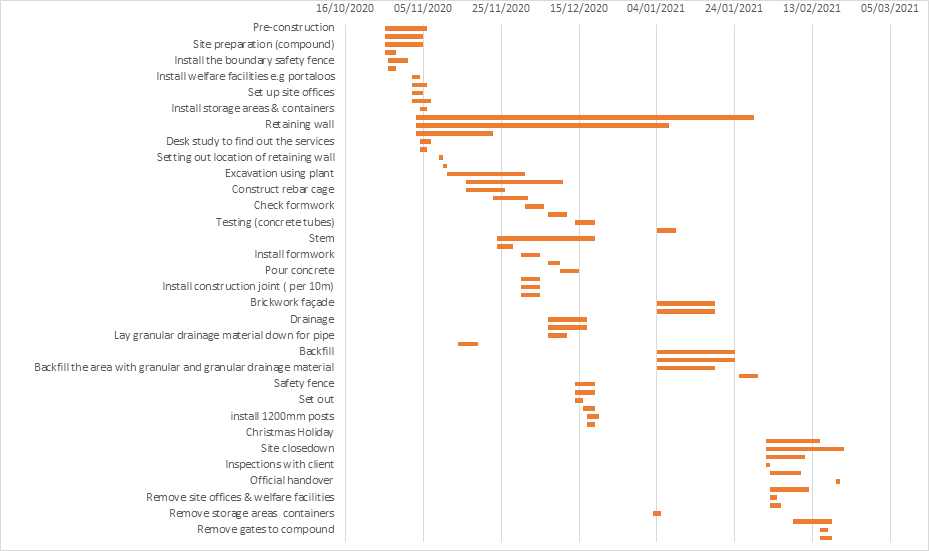

Project Schedule

The figure below shows the project schedule for the M6 motorway project (See attached excel file):

Project schedule: M6 Motorway (Retaining wall)

|

Project schedule: M6 Motorway (Retaining wall)

|

|||||

|

ID |

Name |

Effort estimate |

Planned start date |

Planned end date |

Resource |

|

WBS 1 |

Pre-construction |

|

|

|

|

|

M1.1 |

Site Set-up |

10 |

19/10/2020 |

30/10/2020 |

Project management team |

|

A0 |

Site preparation (compound) |

10 |

19/10/2020 |

02/11/2020 |

Project management team, construction team |

|

A1 |

Create an access road to the site area |

3 |

20/10/2020 |

23/10/2020 |

construction team |

|

A2 |

Install the boundary safety fence |

5 |

21/10/2020 |

27/10/2020 |

construction team |

|

A3 |

Install gates to the works site area |

2 |

21/10/2020 |

23/10/2020 |

construction team |

|

A4 |

Install welfare facilities e.gportaloos |

2 |

26/10/2020 |

28/10/2020 |

construction team |

|

B0 |

Site establish |

10 |

26/10/2020 |

09/11/2020 |

Project management team, construction team |

|

B1 |

Set up site offices |

3 |

27/10/2020 |

30/10/2020 |

construction team |

|

B2 |

Install services and utilities (gas, electricity & water) |

5 |

29/10/2020 |

06/11/2020 |

construction team |

|

B3 |

Install storage areas & containers |

2 |

02/11/2020 |

04/11/2020 |

construction team |

|

WBS 2 |

Construction |

|

|

|

|

|

M1.2 |

Retaining wall |

156 |

09/11/2020 |

15/01/2021 |

Project management team, construction team, consultants |

|

C0 |

Excavation/Preparation |

20 |

09/11/2020 |

04/12/2020 |

construction team |

|

C1 |

Desk study to find out the services |

3 |

09/11/2020 |

11/11/2020 |

Consultants |

|

C2 |

CAT scan to locate the services |

2 |

10/11/2020 |

12/11/2020 |

Consultants |

|

C3 |

Setting out location of retaining wall |

1 |

11/11/2020 |

11/11/2020 |

construction team |

|

C4 |

Assess setting out |

1 |

12/11/2020 |

12/11/2020 |

Consultants |

|

C5 |

Excavation using plant |

20 |

13/11/2020 |

04/11/2020 |

Project management team, construction team |

|

D0 |

Base |

25 |

18/11/2020 |

11/12/2020 |

construction team, consultants |

|

D1-V1 |

Construct rebar cage |

10 |

18/11/2020 |

02/12/2020 |

construction team, consultants |

|

D3-V3 |

Install formwork |

9 |

30/11/2020 |

11/12/2020 |

construction team |

|

D4-V4 |

Check formwork |

5 |

09/12/2020 |

15/12/2020 |

Consultants |

|

D5-V5 |

Pour concrete |

5 |

10/12/2020 |

17/12/2020 |

construction team |

|

D6-V6 |

Testing (concrete tubes) |

5 |

21/12/2020 |

25/12/2020 |

Consultants, project management |

|

D7-V7 |

Strike formwork |

5 |

01/01/2021 |

06/01/2021 |

construction team |

|

E0 |

Stem |

25 |

02/12/2020 |

05/01/2021 |

construction team, consultants |

|

E1-W1 |

Tie stem rebar to base starter |

4 |

02/12/2020 |

08/12/2020 |

construction team |

|

E3-W3 |

Install formwork |

5 |

04/12/2020 |

10/12/2020 |

construction team |

|

E4-W4 |

Check formwork |

3 |

08/12/2020 |

11/12/2020 |

Consultants |

|

E5-W5 |

Pour concrete |

5 |

09/12/2020 |

15/12/2020 |

construction team |

|

F0 |

Joints |

5 |

14/12/2020 |

18/12/2020 |

construction team, consultants |

|

D2-W2 |

Install construction joint (per 10m) |

5 |

14/12/2020 |

18/12/2020 |

construction team |

|

M2-N2 |

Install expansion joint (per 50m) |

5 |

14/12/2020 |

18/12/2020 |

construction team |

|

X0 |

Brickwork façade |

15 |

07/12/2020 |

25/12/2020 |

construction team |

|

X1 |

Install brickwork 225mm |

15 |

07/12/2020 |

25/12/2020 |

construction team |

|

M1.3 |

Drainage |

10 |

07/12/2020 |

18/12/2020 |

Project management team, construction team |

|

G0 |

Drainage pipe |

10 |

07/12/2020 |

18/12/2020 |

construction team |

|

G6-W6 |

Lay granular drainage material down for pipe |

5 |

07/12/2020 |

11/12/2020 |

construction team |

|

G7-W7 |

Install 225 drainage pipe |

5 |

14/12/2020 |

18/12/2020 |

construction team |

|

M1.4 |

Backfill |

20 |

17/12/2020 |

07/01/2021 |

construction team |

|

Y0 |

Backfill of the area |

20 |

17/12/2020 |

07/01/2021 |

construction team |

|

Y1 |

Backfill the area with granular and granular drainage material |

15 |

17/12/2020 |

05/01/2021 |

construction team |

|

Y2 |

Place 225mm top soil |

5 |

02/01/2021 |

09/01/2021 |

construction team |

|

M1.5 |

Safety fence |

5 |

03/01/2021 |

09/01/2021 |

construction team |

|

Z0 |

Installation |

5 |

03/01/2021 |

09/01/2021 |

construction team |

|

Z1 |

Set out |

2 |

03/01/2021 |

05/01/2021 |

Project management team, construction team |

|

Z2 |

Construct 150mm post foundations |

3 |

04/01/2021 |

09/01/2021 |

construction team |

|

Z3 |

install 1200mm posts |

3 |

04/01/2021 |

09/01/2021 |

construction team |

|

Z4 |

Install rail |

2 |

04/01/2021 |

06/01/2021 |

construction team |

|

WBS 3 |

Post-construction |

|

|

|

|

|

M1.6 |

Site closedown |

20 |

07/01/2021 |

12/02/2021 |

Project management team, construction team, consultants |

|

AA0 |

Handover |

10 |

25/01/2021 |

12/02/2021 |

Project management team, construction team, consultants |

|

AA1 |

Inspections with client |

1 |

25/01/2021 |

25/01/2021 |

Project management team, construction team, consultants |

|

AA2 |

Rectify any defects |

8 |

26/01/2021 |

08/02/2021 |

Project management team, construction team, consultants |

|

AA3 |

Official handover |

1 |

12/02/2021 |

12/02/2021 |

Project management team, construction team, consultants |

|

AB0 |

Site takedown |

10 |

07/01/2021 |

21/01/2021 |

Project management team, construction team |

|

AB1 |

Remove site offices & welfare facilities |

2 |

04/02/2021 |

05/02/2021 |

construction team |

|

AB2 |

Remove services & utilities |

3 |

07/01/2021 |

12/01/2021 |

construction team |

|

AB3 |

Remove storage areas &containers |

2 |

07/01/2021 |

11/01/2021 |

construction team |

|

AB4 |

Remove site boundary safety fence |

10 |

07/01/2021 |

21/01/2021 |

construction team |

|

AB5 |

Remove gates to compound |

2 |

19/01/2021 |

21/01/2021 |

construction team |

|

AB6 |

Demobilise staff |

3 |

21/01/2021 |

08/02/2021 |

Project management team |

|

|

|

|

|

|

|

Fig 2.Project Schedule

Precedence manual program

(See attached excel file)

Part 2: Revisedproject schedules and programs

Gantt Chart

Precedence diagram

(See attached excel file)

Ways of speeding up the construction process to amend the program above

The following are measures that can be implemented to amend the project completion date:

1. Increase the number of skilled labourers when installing formwork, brickwork, and concreting works

2. Use modern efficient concrete mixers and pumps when concreting

3. Use more equipment when backfilling

4. Install drainage work during installation of the formwork

5. Install the formwork for the base, stems and joints simultaneously

6. Carry out the desk studies, CAT scans while carry out the site preparation and establishment activities

7. Do the installation of the safety fence while carrying out some site takedown activities

References

Bathhurst, P. & Butler, D., 2010. Building Cost Control Techniques and Economics. 3rd ed. Chicago: Heinemann.

Bogenstatter, U., 2003. Prediction and Optimization of Life-cycle costs. Washington: Build. Res. Information.

Chitkara, K., 2015. Construction Project Management. 3rd ed. New York: Tata McGraw-Hill Foundation.

Feely & Shrimpton, 2018. Cost Management and Reporting in Civil Engineering. 2nd ed. Liverpool: RICS Quantity Surveyors Division.

Flanagan & Tate, 2017. Cost Control in Building Design. 2nd ed. London: Blackwell Science.

Lester, A., 2007. Project Management, Planning and Control: Managing Engineering, construction and manufacturing projects to APM, PMI and BSI standards. 5th ed. London: Butterwoh-Heinamann.

M., P., 2002. A Value and Risk Management Approach to project development. London: New Civil Engineering International.

R., F. & Norman, G., 2009. Life Cycle Costing: Theory and Practice RICS. London: Surveyors Publications.

Sears, K., Sers, G. A. & Clough, R. H., 2010. Construction Project Management: A practical Guide to field consructon Management. 2nd ed. New York: John Wiley & Sons.

Siami-Irdemoosa, E., Dindarloo, S. & Sharifzadeh, 2010.

The Chartered Institute of Building, 2009. The Code of Estimating Practice. London: Rotal Minds Press.

Woodward, J. F., 2017. Construction Project Management: Getting it Right the first time. 3rd ed. Chicago: Telford Publishers.