Supply chain management assignment: Aviation Issues in AJD

Question

Task:

PART A

Blockchain technology is used to establish a single source of truth in a number of industrial scenarios such as: agricultural food supplies, the coffee supply chain and generally across a number of logistics industries. The technology is also used in the aircraft industry to streamline the management of airmiles, the management of the air cargo supply chain, and anti-spoofing GPS systems.

By referring to a single scenario, summarise the critical features that enable blockchain technology to be used to establish a single source of truth and thus protect against counterfeiting in the supply chain of your chosen scenario.

- Suspected ‘Unapproved Parts’ Program Plan (1995), FAA suspected ‘Unapproved Parts’

Task Force, available from:

https://www.faa.gov/aircraft/safety/programs/sups/media/supfnl11.pdf

PART B

Write a technical report which:

- Describes the aircraft parts lifecycle for both new and recycled parts and identifies the parts of the lifecycle where industrial espionage and counterfeiting might pose a risk.

- Evaluates how blockchain technology might support the process of, tracking, tracing and authenticating aircraft engine parts.

- Despite what might appear to be speculative claims concerning the propensity for blockchain technology to become compromised and used in espionage, the overall consensus is that “blockchains distributed consensus mechanism prevents hacking”, and therefore the technology can present safeguards against espionage. Provide a critique of these opposing views.

- The jet engines manufactured by AJD are supplied to companies in multiple international jurisdictions.

- The report is intended for the consumption of the board members of AJD.

Answer

Executive summary

The following renewable energy assignment has developed a project of generating renewable solar energy by the company named Infigen energy. Renewable energy included the generation of electricity power using natural resources such as sun and wind. It has been harmless and less polluted which helped the environment to be less polluted. The company produces clean energy and provides services to the different Australian businesses. The aim of this company examined in the segments of renewable energy assignment has been to create an effective and long-term shared value with the customers and provide them the best service.

Introduction

The report on supply chain management assignment consists of the review for finding aviation issues and developing the idea of counterfeit goods, and the idea of TTA in the aviation supply chain management. The company AJD makes jet engines and it is likely to integrate the blockchain technology to develop the SCM and make it more efficient. The report on supply chain management assignment focuses on the new and recycled parts which integrate counterfeit parts, and critical analysis of blockchain has been developed.

Part A: Review

Aviation industry Issues in Counterfeiting of parts and espionage

Within the aviation industry, a very complex supply chain system exists, and there are various major concerns related to counterfeit goods, or unapproved parts making way without any notice within the supply chain system (Horvath, 2017). Herein supply chain management assignment, these unapproved parts include various products which are counterfeit to original versions, and also include parts which have limited life in comparison to original parts. Use of these parts leads to numerous accidents or aviation incidents, which are of major concern to the final agency providing quality assurance for airworthiness of the products. Hence, there remains an immediate need for tracking, tracing and authenticating the parts, which are genuine and which are useful within the aircraft industry. The major primary need for counterfeiting parts within the supply chain process in aviation industry is profit (Roper, 2013). Hence, within this supply chain management assignment, the aviation industry has been chosen.

And there are various processes which thereby makes this industry susceptible to such types of issues. Two major reasons behind the counterfeiting is long life cycle of the parts for the aircrafts manufactured and the DMSMS, diminishing manufacturing sources and material shortages. Mostly, this industry makes products have a long life cycle and sustenance. During the lifetime of the aircraft several parts which includes mostly the microchips or the electrical components changes (Zhou, 2013). The computers which are used to change the design or the parts of the aircraft are likely to change an average of seven times. The various processes in relation to manufacturing of the aircraft and the parts are likely to change three times or more; whereas the systems used within the aircraft are likely to change more than 9 times during the whole lifetime. As technology develops further, the rate of change also gets affected (Horvath, 2017).

Hence, as there are many times changes occurring during the life cycle of the aircraft, various parts might be procured which no longer belongs from the original source or original equipment manufacturer OEM, or from the authorised dealers or resellers (Tehranipoor et al., 2015). Microcircuits and other parts, are often procured from the distribution channels not belonging from the dealers of OEMs, and hence, risks might accrue wherein these parts might not be from the original manufacturer, which increases the rate of depreciation and the quality provided by the aircraft services. The most important risks which are posed within the aircraft manufacturing industry are the counterfeit of the electronic parts risking the expenses, time, safety, schedule, and mission success rate (Stevenson and Busby, 2015).

What are the critical features of block chain in mitigating the issues through TTA and to be used to establish a single source of truth mentioned in the supply chain management assignment?

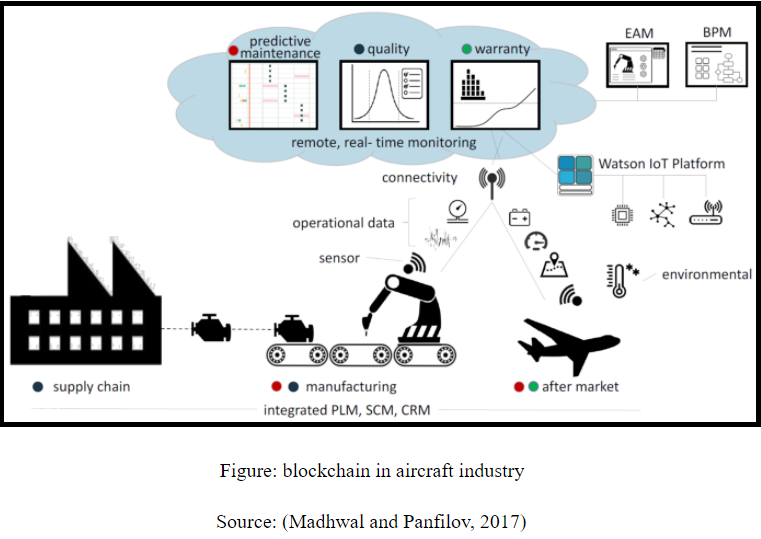

Block-chain is a form of digital ledger, which is self-updating and which constantly validates the information updated, in the virtual world; which has high difficulty in forging. In the aviation industry, supply chains are vast and complex; and sometimes products are designed in one location, manufactured in some other location, and sold in different market places (Madhwal and Panfilov, 2017). Moreover in the case of AJD explored in the supply chain management assignment, the Jet engines manufactured are often supplied to aviation companies in other countries, throughout the globe. Before reaching service buyers, the aircrafts are passes through various warehouses, regions, weather conditions, which need to be completely traced and tracked and authenticated. For proper TTA features within the aviation industry, utilising block-chain has been a disruptive technology, which replaces the conventional tools used in the present situations (Kshetri, 2018). The present TTA applications discussed in the context of supply chain management assignment often have limitations, and are often unsecure platforms, where data can be forged or have security breaches.

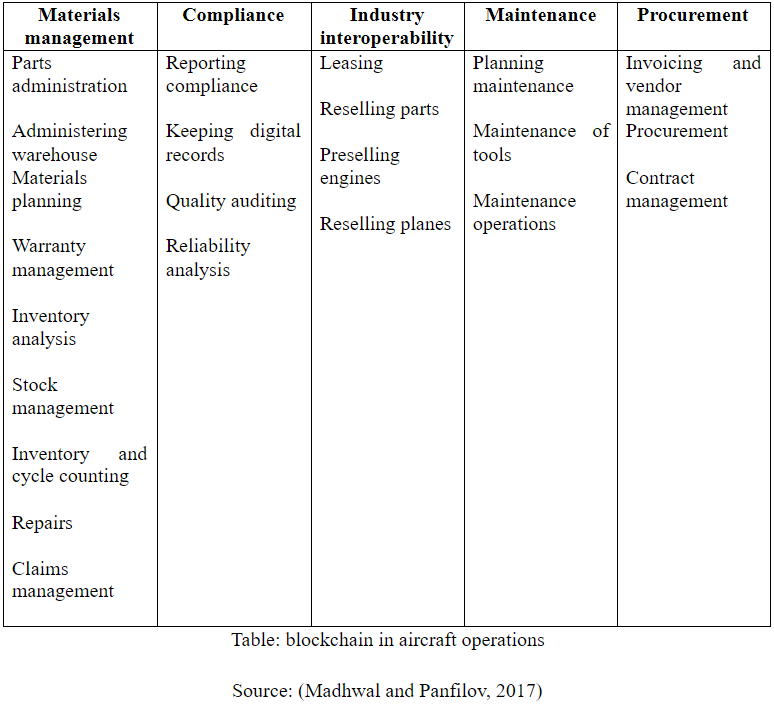

The study developed in the supply chain management assignment signifies that the whole process of the blockchain technology within the industry starts from the supply chain processes, integrates the manufacturing processes, monitoring and controlling maintenance, and also after sales services when parts maintenance is done within the aircraft (Madhwal and Panfilov, 2017). The blockchain ledger tracks, traces and authenticates and records information of the area and location from which parts have been accessed, their use, their replacement, replacement parts, and again stores all this information for easier retrieval during the whole lifecycle of the aircraft. The research on supply chain management assignment illustrates that the transaction of the overall operation of blockchain technology within aviation is done through interconnected data exchanges, and drawing insights from different parties, suppliers and buyers. The interoperability between origin, journey and industry is mostly performed through blockchain (Madhwal and Panfilov, 2017). The origin through blockchain enables in reliability and tracing the procurement details of the parts used. Throughout the lifecycle journey, the status of parts used and replaced and tracking repairs history is made. Data exchange for industry interoperability is made, and then the maintenance, repair operations value chain is mapped. The various transactions are provided in the table below within this supply chain management assignment:

86% of the world’s aerospace and aircraft manufacturing companies have decided to develop block-chain technology and integrate this disruptive technology within the corporate systems of the companies to improve trust, traceability and authentication of parts in aviation supply chain. The major features of the block-chain mentioned in the supply chain management assignment, is the security provided by the technology, its immutability and their decentralised capacity (Mandolla et al., 2019). The data stored is immutable, and cannot be changed or deleted, through secure transaction. Being an open ledger, the process is decentralised, and having client server model, is not maintained by a central authority. Lastly, it is a peer to peer network, not requiring third party authority for authorising transactions. These features outlined in this section of supply chain management assignment helps aviation industry to decrease the maintenance expenses, increase better parts selection and aircraft availability; and reduce any form of errors through tracking counterfeit parts (Kshetri, 2018). Moreover using block-chain reduces chances of errors and improves the efficiency of the supply chain system. Within the supply chain management system in aviation, block-chain works well within parts tracking, to reduce the ill effect of counterfeiting or espionage of parts throughout the engine life time or aircraft life time (Lacity, 2018). The use of block-chain is not only limited to tracking, tracing and authenticating the parts from OEMs, but also helps in maintenance logs, ensuring legitimate production of parts, and developing the airworthiness of the aircraft. Moreover various requirements and eligibility to quality airworthiness is maintained through block-chain, which also helps in offering an immutable record, and also maintaining which person handles what.

One such block-chain noted in the supply chain management assignment which is used for parts maintenance and tracking is Enspan, which is a pioneer technology offering efficiency in developing proper documentation for lifecycle maintenance of asset (Francisco and Swanson, 2018). Moreover through this TTA compliance, the companies like AJD, also can purchase or sell parts through legitimate confidence, provided the documentations are accurate and all the parts are maintained and legally compliant with OEM (Jacobovitz, 2016).

Part B: technical report on supply chain management assignment

Aircraft parts lifecycle for both new and recycled parts and areas of industrial espionage and counterfeiting risk within the aviation manufacturing.

The lifecycle of an aircraft mostly includes different phases including designing, production, operations and decommissioning the aircraft. The aircraft is made of different parts and specification, and each part has a certain lifecycle, which is determined by their life from the OEMs (Wagner and Walton, 2016). The design phase includes production, operation and recycling the aircrafts and the parts, through performance testing, reliability, assembling, manufacturing and recycling, after testing and quality assurances. The production phase includes planning and development, supply of various component parts, assembling, manufacturing, and testing. The operations parts include scheduling the aircraft parts, maintenance, repair, and recycling of the components when the lifecyle ends (Vieira and Loures, 2016). Throughout the vast lifecycle of the aircraft, every component is replaced, when it fails to function. This might happen on an average of five to seven times, during the whole lifecycle of the aircraft, mostly electronic parts, machines, and others. As mentioned herein supply chain management assignment, the major parts include aluminium, glass, carbon, optical fibres, textiles, wires, circuits, carpets, seats, engines, landing gear, microchips, and other high value parts. Most of the recycled parts include recycling metals from the debris, and the body, leather, useful metals etc. These parts are mostly also supplied and sometimes parts are counterfeited to decrease costs, and also reducing conformity to airworthiness. To replace the existing faulty part, another part is used, procured through the supply chain. However, problem is that the part might not belong from the original equipment manufacturer, and might be suspected unapproved parts (Yildirim and Abanteriba, 2012). Since 2011, the Federal Aviation Administration claims that there have been 3000 discovered SUPs within the supply chain of the aircraft manufacturing industry, due to pressure to control costs, shortages of OEMs, and this leads to loss of insurance coverage if the parts are not genuine, due to lack of certification. Some aircraft manufacturers want to profit by procuring cheap parts, and uses the cheap SUPs, whenever a part fails throughout the lifecycle of the aircraft, which reduces the airworthiness of the aircrafts and the security safety options for passengers (Vieira and Loures, 2016).

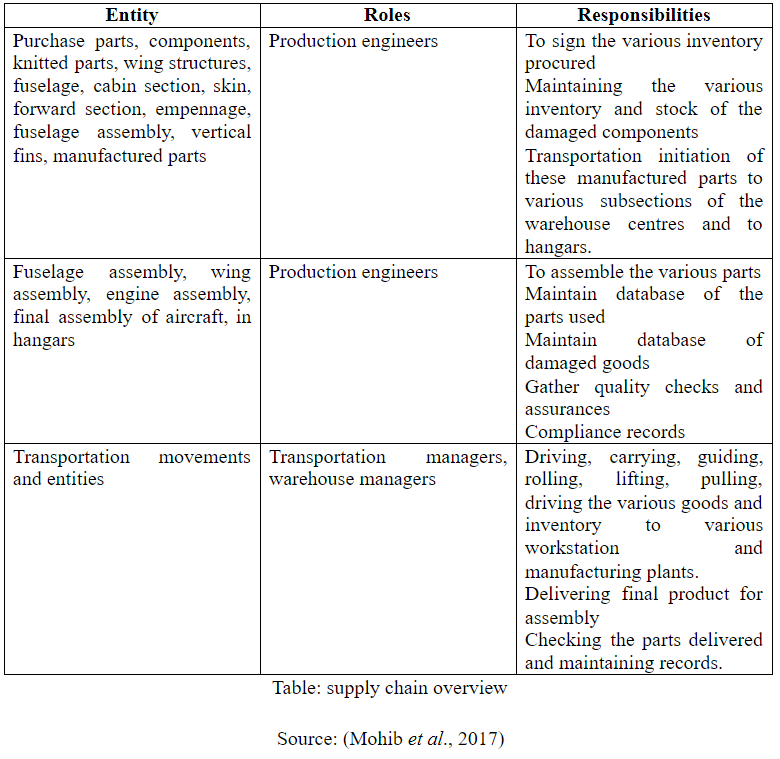

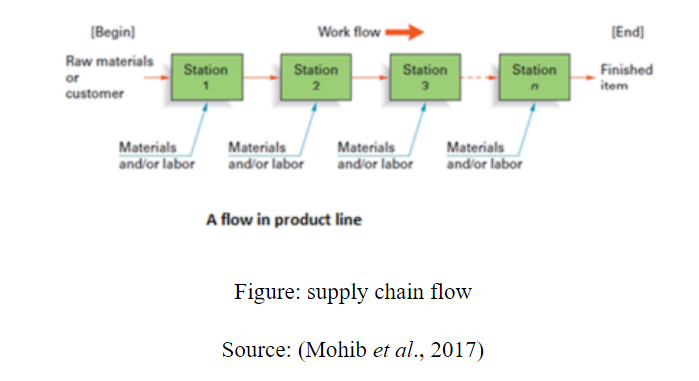

It is discussed in this supply chain management assignment that the major entities within the supply chain processes of the aircrafts include hangars, manufacturing plants, work centres distribution agents, transporting companies, transportation modes and other processes involved. The major roles within the supply chain processes include the production engineers, the drivers, the warehouse security, the managers, and the database keepers.

Throughout the vast lifecycle of the aircraft explored in the supply chain management assignment, every component is replaced, when it fails to function. This might happen on an average of five to seven times, during the whole lifecycle of the aircraft, mostly electronic parts, machines, and others (Mohib et al., 2017). The major parts include aluminium, glass, carbon, optical fibres, textiles, wires, circuits, carpets, seats, engines, landing gear, microchips, and other high value parts. Most of the recycled parts include recycling metals from the debris, and the body, leather, useful metals etc. These parts are mostly also supplied and sometimes parts are counterfeited to decrease costs, and also reducing conformity to airworthiness.

To replace the existing faulty part, another part is used, procured through the supply chain. However, problem raised in this section of supply chain management assignment is that the part might not belong from the original equipment manufacturer, and might be suspected unapproved parts (Yildirim and Abanteriba, 2012). Since 2011, the Federal Aviation Administration claims that there have been 3000 discovered SUPs within the supply chain of the aircraft manufacturing industry, due to pressure to control costs, shortages of OEMs, and this leads to loss of insurance coverage if the parts are not genuine, due to lack of certification. Some aircraft manufacturers want to profit by procuring cheap parts, and use the cheap SUPs, whenever a part fails throughout the lifecycle of the aircraft, which reduces the airworthiness of the aircrafts and the security safety options for passengers (Vieira and Loures, 2016).

As noted in the supply chain management assignment, there are parts recognised which are used in the manufacturing of aircrafts, which have limited lifetime, and limited life status. The life limited parts have a replacement limit, which is centred on the airworthiness and certifies mandatory replacements for the parts. The life status includes the total number of lifecycles, the time, and replacement limits of these parts (Holmström et al., 2010). The certification process, mentions the life limitedness of the part, and leads to the mandatory replacement of the parts. The FAA through the ‘instructions of continued airworthiness’, maintains the manual for the parts, which requires possible mandatory replacements. The type certificate of the parts provides the limit, and the parts are replaced after the limit is reached including in engines, aircrafts or in propellers (Ayeni et al., 2011).

The various approved parts within the aircraft manufacturing include the following points mentioned in this supply chain management assignment:

- Parts which have a product or type certificate

- Parts manufacturing approval acclaimed parts

- Parts which are produced by the original owner of the aircraft, and who is liable to maintaining own products

- Parts which have the certificate from FAA Technical Standard order

- Standard parts which are also conformed to specifications set by US; like bolts and nuts (Holmström et al., 2010).

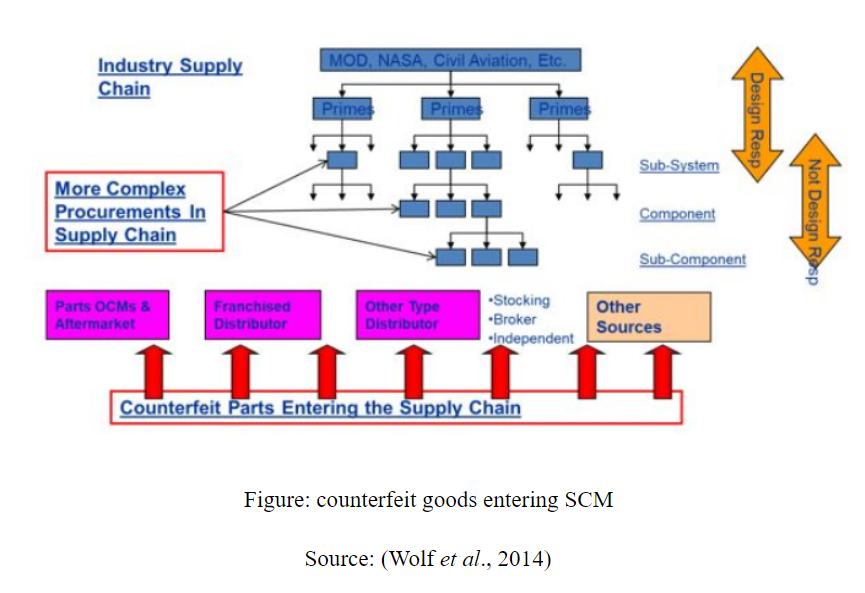

The unapproved counterfeit parts are often used when, the validity of the approved authentic parts end, to save cost and make profit. The use of such counterfeit parts might reduce the airworthiness of the aircrafts, and generally does not get approved by the FAA regulations. The counterfeit parts outlined in the supply chain management assignment are misrepresented as being produced and certified under an approved body; and these parts might also have design limits, and sold to defraud the procurer (Kshetri, 2018). In most cases, throughout the production and maintenance time of the aircraft, the counterfeit products makes way into the supply chain mechanism.

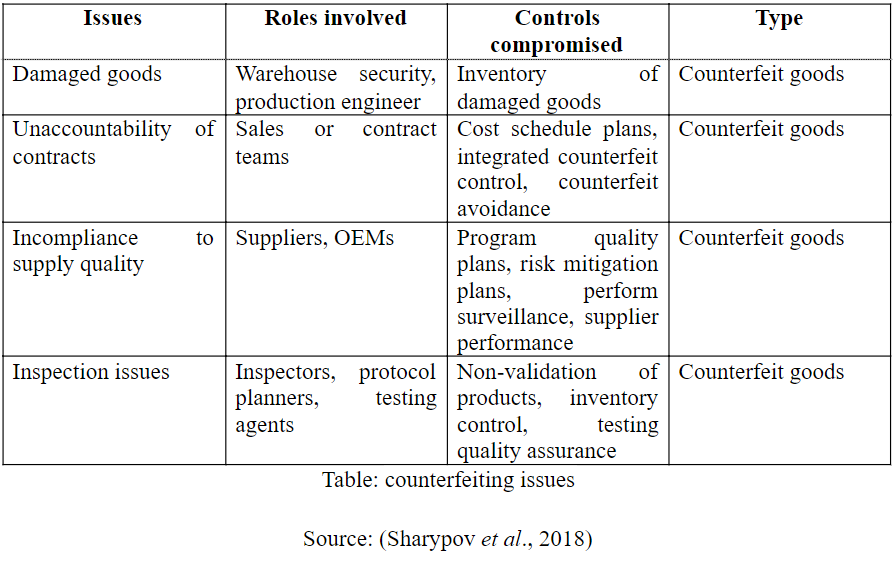

Counterfeit parts enter into the industry trough loopholes in the supply chain management processes, and within the specified chains the risk for the counterfeit part increases, and the parts enter the SCM through the OEMs, the after-market sellers, the franchised distributors, other distributors like brokers, stockists and independent distributors and other sources of entry (Wolf et al., 2014). The study provided in the supply chain management assignment illustrates that the quality management system should be enhanced to reduce the risks from the counterfeit goods and the espionage products. There are various issues which include the risks of damaged goods, unaccountability of sales contracts while procuring materials from the suppliers, inspection issues regarding quality maintenance and incompliance of the supplied goods (Sharypov et al., 2018). Such issues listed in the context of supply chain management assignment are related to the counterfeit goods entering the supply chain of the aviation industries and are some typical issues faced by AJD while handling engine manufacturing.

Whenever some parts have reaches lifetime status and are being replaced, unapproved parts might enter into the system to reduce the costs. These counterfeit parts noted in the supply chain management assignment must be identified, by analysing the prices difference between the part and the OEM parts; having a shorter delivery schedule; part lacking conformity of certification; and inability to provide FAA certification. These counterfeit aircraft parts might enter throughout the whole system of manufacturing and maintenance of the vehicle (Mandolla et al., 2019). The implication of these counterfeit goods and espionages entering into the SCM leads to threat of airworthiness decrease and accidents which needs to be stopped through decentralised means.

Use of block-chain technology might support the process of, tracking, tracing and authenticating aircraft engine parts

The investigation carried on this supply chain management assignment mentions that a large number of accidents and deterioration of airworthiness of the aircraft has led to the decision to involve IT and block-chain technology into the forefront for tracking the various parts within the supply chain management system, so as to track parts based on certification provided by the FAA (Skaves, 2015). Block-chain has been previously known for its secured provisions towards bit-coin crypto currency, and its technology has also been used for tracking, maintaining records, and transferring parts and assets across different industries, improving efficiency of operations and reducing unwanted expenses. The most important challenge started in the supply chain management assignment which is faced by the aerospace industry is to track, trace and maintain the authenticity of their parts to increase the airworthiness of the aircrafts. To develop the proper parts management and reduce the infiltration of the unwanted counterfeit parts, proper security, and tracing must be envisaged; to reduce any form of accidents in flights and provide safety checks on the operational authenticity of the parts (Carmichael et al., 2018).

The main benefit of utilising block-chain to solve this problem identified in this case of supply chain management assignment is the use of encrypted secure audit trail which helps in developing the traceability of the parts, from the source till its use in the manufacturing and maintenance throughout the aircraft lifecycle. Block-chain improves the efficiency of operations by ensuring transparency, while developing customer feedback and also by sharing data, and this solution can be applied to tracking all the parts throughout the supply chain, from delivery to the services (Vieira and Loures, 2016).The aircraft industries need to understand the proper parts which are being used, and their sources; along with proper certificates conforming their authenticity and which can be helped in tracing the parts back to the equipment manufacturer, during some aircraft issues like accidents for legal claims for liability. Honeywell has also helped in transforming all their aircraft parts businesses to the block-chain system, by tracking and tracing the parts to be delivered online. Moreover the total inventory control system along with supply chain management system of the parts can be virtually tracked all the while providing enough security (Goncalves and Kokkolaras, 2017).

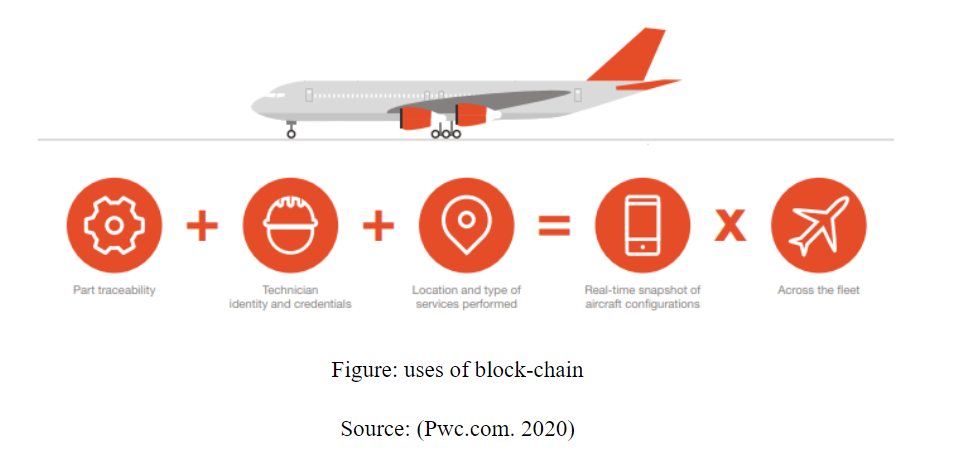

To address the growth of commercial aircraft demand in the next 20 years within this supply chain management assignment, with more than 40,000 aircrafts needed; companies have started relying on the wider transparency and data immutability provided by block-chain to streamline cost and operations. All planes need hundreds and thousands of parts, to million parts, and the manufacturer needs to keep a record of all the parts, as each and every one is vital (Pwc.com. 2020). The aircraft also needs to maintain the part through maintenance, repair and overhaul mechanism MRO, including stocking, restocking, supplying, and to improve credibility for provenance, airworthiness, through testing. The data of these parts are distributed throughout the suppliers, the vendors, and customers of the parts; and the decentralisation, and immutable nature of block-chain, are deemed to overcome such issues (Pwc.com. 2020).

Block-chain uses a peer to peer network for transmitting data, and records the various technologies used, through the parts that are removed or are installed; identifying the source of parts and the maintenance report of the parts. Moreover information is provided, which improves the visibility across peers, and not third-party agents; thereby safeguarding vital information form the competitors (Di Vaio and Varriale, 2020). According to the research on supply chain management assignment, all the parts which are used or reused in the aircraft are provided a certificate and every time this part is inspected for maintenance these certificated logged in block-chain can be used. The data is mostly saved in the system using the tail umber of the vehicles, the location, configuration, and the area where maintenance is performed. Moreover these certificates is used for tracing the whole journey of the parts, tracking the authenticity by recording the conformity to FAA standards, and the whole data from supply to sales within a specified time period (Pwc.com. 2020).

Transparency provided by block-chain includes part traceability, identity of technician and credentials, location of maintenance and services performed, across the fleet and aircraft configurations.

It is specified in this supply chain management assignment that using block-chain helps not only in TTA, but streamlines costs, improves maintenance, reduces losses, and improves airplane value, increases productivity; improving the chances of industry revenue generation by more than 4%; and keeping all information stored throughout the life of the aircraft through a commercialised ecosystem (Pwc.com. 2020). The technology enables in tracing raw materials, finished products, services at factory floor, improves distribution, track’s progresses, MRO provisions, increasing visibility through supply chain, and reduces the chances of counterfeit products from resellers, improves maintenance, guarantees in place of warrantees, improves finance and workforce.

Claims concerning the propensity for block-chain technology and block-chain technology can present safeguards against espionage. A critique of opposing views

A CIA intelligence officer Andrew Bustamante has provided a claim of block-chain being a high threat to the American security. The CIA agent identified in the supply chain management assignment has developed knowledge for espionage, and being an Airforce veteran, criticises block-chain as a learning system where international espionage tactics to develop everyday life (Cointelegraph, 2020). To a response made by others on the technology which poses highest threat, Bustamante replied it being block-chain (Cointelegraph, 2020). According to him, block-chain is powerful, and the quantum computing techniques might have faltering crypto protection, and the possibility of anonymous transactions, might lead to falsification of data. Moreover if the block-chain gets hijacked it leads to greater security risks, leaking vital confidential information, and leading to hacking of the crypto currency and risking various vital operations, which are part of national security. Moreover using the crypto currency, various other illegal businesses can be funded, which reduces the main point of developing block-chain for national good. However, the readings outlined in the supply chain management assignment determines that there are frequent criticism on replacing and eliminating trust, and there is realisation that block-chain technology has more positive hypes rather than values (Golosova and Romanovs, 2018).

Block-chains have distributed, central ledgers; consensus algorithm wherein all ledgers are same; and currency is publicly traded. The pure virtuality of this technology doesnot appeal to the trust by humans, and for this reason many proponents criticise on the nature of block-chains. The fear of cybercrimes and hacking is the essential problem, as hacking means losing all information at one go; which is a high risk (Niranjanamurthy et al., 2019). There are also chances of centralisation of the system, which makes it more feasible for hackers to attack such systems. The scepticism on block-chain exists on same reason, for which the company might lose their competitive advantage to their competitors. The main problem discussed in this aspect of supply chain management assignment is that end users donot actually want to use block-chain due to mistrust of the totality of the system. Moreover, this also might lead to greater expenses in transactions, and there remain adaptation problems of the organisation to the system (Golosova and Romanovs, 2018). The complication with Block-chain also poses a problem, and often leads to loss in performance, if not adapted rightly. Moreover disruptive technology is often viewed with apprehension, by analysts and within SCM that increases risk.

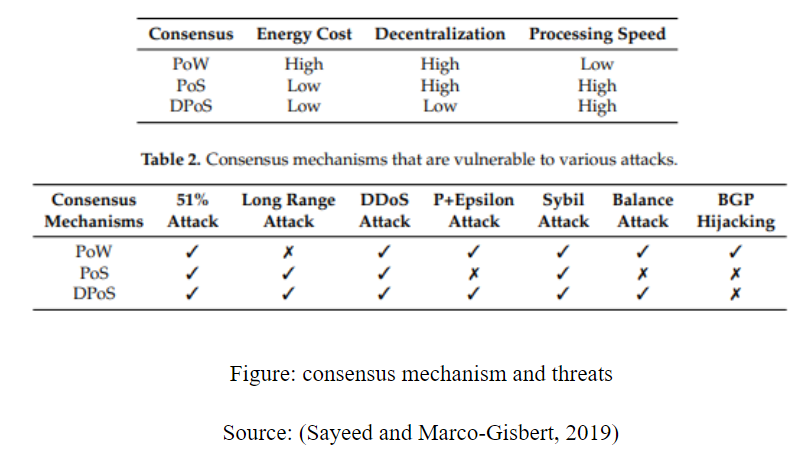

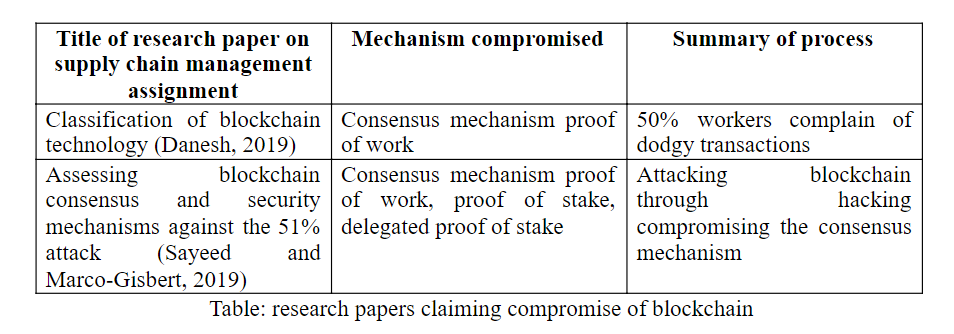

The consensus mechanism in blockchain helps in developing a fault-tolerant mechanism which helps in developing agreement over single data value, among the multi-agent systems. Blockchains operate through decentralised mechanisms, and thereby various people throughout the various stages contribute to the information build-up, working on principles of verifications and authentications (Di Vaio, and Varriale, 2020). This consensus mechanism algorithm illustrated in the supply chain management assignment works on proof of work, proof of capacity and proof of stake, building security efficiency, functionability, and security. Within the aerospace industry the consensus mechanism mostly used includes the Proof of stake and Delegated proof of stake mechanism, wherein highly vested interest is maintained for integrity of network, to validate the fraudulent transactions (Dai et al., 2017). AJD similarly finds PoS, DPoS mechanism for improving the validity and consensus mechanism of the blockchain technology for improving the decentralised features and developing the overall system more efficiently.

As per the investigation carried on this supply chain management assignment, the counterviews have also been generated, which provides a positive light to the block-chain technology, and which has till now provided better efficiency, encryption and security to the operations processes. There is proof of how block-chain has revolutionised the aviation manufacturing industry with the help of quantum computing and cyber security through cloud computing techniques (Gatteschi et al., 2018). The supply chain in aviation industry includes the vendors, suppliers, OEMs, Tier 1 suppliers, third party MROs, and for keeping the information intact, a secure and protected ledger is mostly required to improve the supply chain. As the contents are peer to peer encrypted, the content cannot be tampered. There are various hacking mechanisms to reduce the validity of the aerospace industry consensus mechanism. The various hacking methods which can be used includes 51% attack, long range attacks, distributed denial of services, P+ Epsilon attack, Sybil attacks, balance attacks, and border gateway protocol hijacking (Sayeed and Marco-Gisbert, 2019). It is evident in the supply chain management assignment that for those systems following the Pos and DPos consensus mechanism, the long-range attacks can reduce and compromise the situation of the blockchain, and longer chains can be generated as augmentation of chains are not identified in PoS mechanism. Denial of service attacks also compromise information related to transactions within blockchain which might further reduce their efficiency. Moreover through Sybil attacks the consensus can be breached by creating many false identities within the peer-to-peer network, created unauthorised transactions and outvoting honest nodes (Sayeed and Marco-Gisbert, 2019).

In the case of AJD considered in the supply chain management assignment, the transaction occurs through international parties, as the company leases or supplies across Britain, France, America, China and Malaysia. Hence, it is stated herein supply chain management assignment that international agreements, various forms of payment, parts maintenance, the supply network, the distribution along with the parts which are supplied from OMEs for replacing after lifetime can be envisaged throughout the use of block-chain (O’Dair and Beaven, 2017). However while designing the block-chain for the company it must be kept in mind to develop the cyber security, audit, compliance, legal specialists for generating decisions from the start. This helps in developing right ecosystem for the company.

Conclusion

From the overall discussion on supply chain management assignment, counterfeit goods throughout the lifecycle of the aircraft industry enables in reducing the vitality of the aircraft as the parts are replaced by counterfeits, thereby marking the greatest industrial espionage of all times. Block-chain helps in deterring such aviation espionages, reducing counterfeiting, improving the capacity of maintenance of parts and tracking the authentic parts for the industry. This is to improve the score, safety, security and airworthiness of the components manufactured, within aircraft industry.

References

Ayeni, P., Baines, T., Lightfoot, H. and Ball, P., 2011. State-of-the-art of ‘Lean’in the aviation maintenance, repair, and overhaul industry. Supply chain management assignment Proceedings of the Institution of Mechanical Engineers, Part B: journal of engineering manufacture, 225(11), pp.2108-2123.

Carmichael, D.B., Kutz, M.N. and Brown, D.M., 2018. FAA “Captured?” Is the Federal Aviation Administration Subject to “Capture” by the Aviation Industry?. The Collegiate Aviation Review International, 21(1).

Cointelegraph. 2020. Ex-CIA Official Claims Blockchain Is ‘Biggest Threat’ To Future Of US National Security. [online] Available at:

Dai, F., Shi, Y., Meng, N., Wei, L. and Ye, Z., 2017, November. From Bitcoin to cybersecurity: A comparative study of blockchain application and security issues. In 2017 4th International Conference on Systems and Informatics (ICSAI) (pp. 975-979). IEEE.

Di Vaio, A. and Varriale, L., 2020. Blockchain technology in supply chain management for sustainable performance: Evidence from the airport industry. International Journal of Information Management, 52, p.102014.

Di Vaio, A. and Varriale, L., 2020. Blockchain technology in supply chain management for sustainable performance: Evidence from the airport industry. International Journal of Information Management, 52, p.102014.

Francisco, K. and Swanson, D., 2018. The supply chain has no clothes: Technology adoption of blockchain for supply chain transparency. Supply chain management assignment Logistics, 2(1), p.2.

Gatteschi, V., Lamberti, F., Demartini, C., Pranteda, C. and Santamaria, V., 2018. To blockchain or not to blockchain: That is the question. IT Professional, 20(2), pp.62-74.

Golosova, J. and Romanovs, A., 2018, November. The advantages and disadvantages of the blockchain technology. In 2018 IEEE 6th Workshop on Advances in Information, Electronic and Electrical Engineering (AIEEE) (pp. 1-6). IEEE.

Goncalves, C. and Kokkolaras, M., 2017. Modeling the relationship between aviation original equipment manufacturers and maintenance, repair and overhaul enterprises from a product-service system perspective. In DS 87-3 Proceedings of the 21st International Conference on Engineering Design (ICED 17) Vol 3: Product, Services and Systems Design, Vancouver, Canada, 21-25.08. 2017 (pp. 389-398).

Holmström, J., Partanen, J., Tuomi, J. and Walter, M., 2010. Rapid manufacturing in the spare parts supply chain. Journal of Manufacturing Technology Management.

Horvath, B.T., 2017. Not All Parts Are Created Equal: The Impact Of Counterfeit Parts In The Air Force Supply Chain. Air War College, Air University Maxwell AFB United States.

Jacobovitz, O., 2016. Blockchain for identity management. The Lynne and William Frankel Center for Computer Science Department of Computer Science. Ben-Gurion University, Beer Sheva.

Kshetri, N., 2018. 1 Blockchain’s roles in meeting key supply chain management objectives. Supply chain management assignment International Journal of Information Management, 39, pp.80-89.

Lacity, M.C., 2018. Addressing key challenges to making enterprise blockchain applications a reality. MIS Quarterly Executive, 17(3), pp.201-222.

Madhwal, Y. and Panfilov, P.B., 2017. BLOCKCHAIN AND SUPPLY CHAIN MANAGEMENT: AIRCRAFTS'PARTS'BUSINESS CASE. Annals of DAAAM & Proceedings, 28.

Madhwal, Y. and Panfilov, P.B., 2017. BLOCKCHAIN AND SUPPLY CHAIN MANAGEMENT: AIRCRAFTS'PARTS'BUSINESS CASE. Annals of DAAAM & Proceedings, 28.

Mandolla, C., Petruzzelli, A.M., Percoco, G. and Urbinati, A., 2019. Building a digital twin for additive manufacturing through the exploitation of blockchain: A case analysis of the aircraft industry. Computers in Industry, 109, pp.134-152.

Mohib, A.A., Azad, R., Haque, S. and Hossain, M.F., 2017. Logistics and Supply Chain: An Overview of Business Jet Aircraft Manufacturing.

Niranjanamurthy, M., Nithya, B.N. and Jagannatha, S., 2019. Analysis of blockchain technology: pros, cons and SWOT. Cluster Computing, 22(6), pp.14743-14757.

O’Dair, M. and Beaven, Z., 2017. The networked record industry: How blockchain technology could transform the record industry. Strategic Change, 26(5), pp.471-480.

Pwc.com. 2020. [online] Available at:

Roper, C., 2013. Trade secret theft, industrial espionage, and the China threat. CRC Press.

Sayeed, S. and Marco-Gisbert, H., 2019. Assessing blockchain consensus and security mechanisms against the 51% attack. Supply chain management assignment Applied Sciences, 9(9), p.1788.

Sharypov, A., Brusnikin, V., Koval, S., Glukhov, G. and Gubanov, O., 2018. Aircraft components life cycle monitoring as a tool for identifying inauthentic aviation equipment items. International Journal of Mechanical Engineering and Technology (IJMET), 9(7), pp.612-620.

Skaves, P., 2015, April. FAA aircraft systems information security protection overview. In 2015 Integrated Communication, Navigation and Surveillance Conference (ICNS) (pp. A1-1). IEEE.

Stevenson, M. and Busby, J., 2015. An exploratory analysis of counterfeiting strategies. International Journal of Operations & Production Management.

Tehranipoor, M.M., Guin, U. and Forte, D., 2015. Counterfeit integrated circuits. In Counterfeit Integrated Circuits (pp. 15-36). Springer, Cham.

Vieira, D.R. and Loures, P.L., 2016. Maintenance, repair and overhaul (MRO) fundamentals and strategies: An aeronautical industry overview. International Journal of Computer Applications, 135(12), pp.21-29.

Vieira, D.R. and Loures, P.L., 2016. Maintenance, repair and overhaul (MRO) fundamentals and strategies: An aeronautical industry overview. International Journal of Computer Applications, 135(12), pp.21-29.

Wagner, S.M. and Walton, R.O., 2016. Additive manufacturing’s impact and future in the aviation industry. Production Planning & Control, 27(13), pp.1124-1130.

Wolf, M., Minzlaff, M. and Moser, M., 2014. Information technology security threats to modern e-enabled aircraft: A cautionary note. Journal of Aerospace Information Systems, 11(7), pp.447-457.

Yildirim, U. and Abanteriba, S., 2012. Manufacture, qualification and approval of new aviation turbine fuels and additives. Supply chain management assignment Procedia engineering, 49, pp.310-315.

Zhou, Y., 2013. Electronic Waste Export Regulations: How the Responsible Electronics Recycling Act Can Protect the Defense Supply Chain from Counterfeit Electronic Parts. Pub. Cont. LJ, 43, p.527.